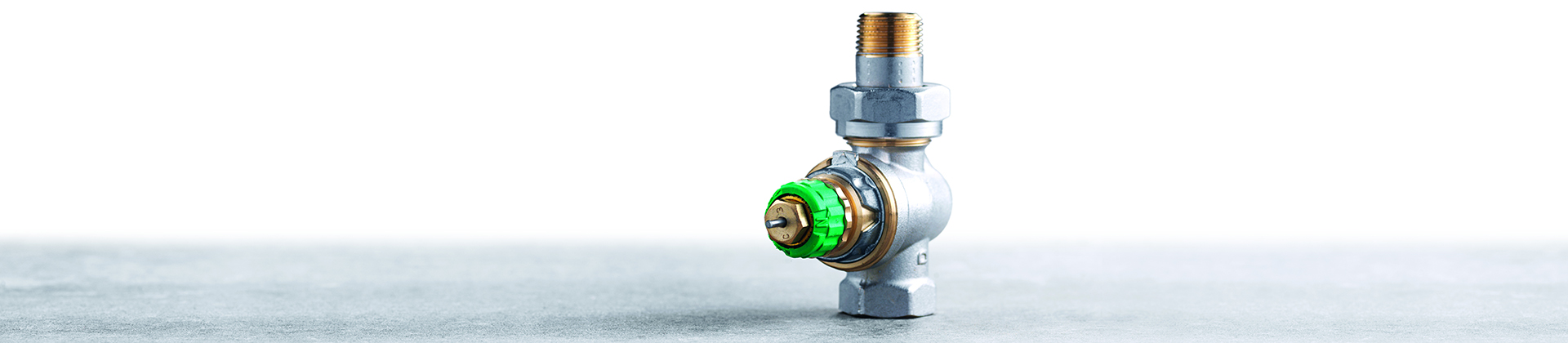

Danfoss Dynamic Valve™: a simple solution to a daily challenge

Danfoss Dynamic Valve™ is an innovative radiator valve with a 2-in-1 valve design. It combines a thermostatic radiator valve and a differential pressure controller for accurate temperature control and automatic hydronic balancing in a single product.

The built-in differential pressure controller eliminates pressure fluctuations in a two-pipe heating system. By using Dynamic Valve™ a perfectly controlled and automatic hydronic balanced heating system is simply established.

For designers

Dynamic Valve™ is good news for everybody involved in designing or specifying of two-pipe heating systems. It has all the advantages of automatic hydronic balancing combined with optimal temperature control.

For installers

By installing the valves you also install automatic balancing at the same time. To commission the system correctly the valves just have to be set to correct maximum flow at each radiator.

For building owners

Dynamic Valve™ is a product typical to use in residential buildings. Many owners, occupants and other users will recognize typical heating problems like noise, uneven heating and high energy bills. The indoor comfort will be greatly increased when Dynamic Valve™ is used.

Features and benefits

A 2-in-1 valve design for temperature control and automatic balancing

Built-in differential pressure controller

Maximum differential pressure 60 kPa

Limitation of maximum flow between 10 – 135 liters per hour

Available in DN 10/15/20

Available in Straight, Angle, Angle UK, Angle left and Angle right models

Available in NF (Norm France) and DIN (Deutsche Industrial Norms) standards

See how the Danfoss Dynamic Valve™ works

Presentation of what is special about this thermostatic radiator valve, how it works and what the benefits are.

Videos

Related products

Easy measuring with dP tool™

There is only one requirement to ensure the built-in differential pressure controller works as it should. That is the total differential pressure over the Dynamic Valve™ is 10 kPa. If this pressure loss is present on the valve furthest from the pump, the system is correctly commissioned. To check if the required pressure loss is present use the dP tool™. It's a simple and unique tool that measures the available differential pressure.