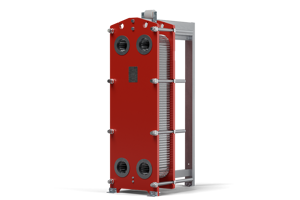

Our hygienic gasketed plate heat exchangers are engineered to meet the most stringent hygienic requirements and provide superior processing. Our solutions utilize FDA-compliant materials to ensure the best quality of your end-product.

Our hygienic gasketed plate heat exchangers are well-suited for a variety of applications in the food and beverage industry. Whether it’s pasteurization in dairy processing, cooling in beverage production, or heating in brewery operations, Danfoss' hygienic frames provide the flexibility and efficiency needed to optimize your processes. From egg pasteurization to fruit juice production, we ensure hygienic standards are met while delivering exceptional performance across all applications

Why choose Danfoss hygienic gasketed plate heat exchangers

At Danfoss, we prioritize your product’s quality by tailoring each heat exchanger to your specific needs. Our advanced plate technology guarantees gentle media treatment, precise flow control, and optimal temperature profiles, ensuring the perfect conditions for your application.

Features and benefits

-

Hygienic frame design: Built to meet the latest industry standards, our frames comply with FDA material standards, ensuring safe and hygienic processing.

-

Superior plate technology: Achieve the highest product quality with gentle media treatment, precise flow control, and perfect temperature profiles.

-

Effortless maintenance: Choose between cladded or solid stainless steel frames designed for easy access, allowing quick inspection, maintenance, or cleaning, including cleaning in place (CIP).

-

Energy efficiency: Our regenerative pasteurizers can recycle up to 95% of energy, offering substantial savings on power consumption.

Common applications

Our hygienic gasketed plate heat exchangers are versatile and ideal for a wide range of applications, including:

- Beverages: Carbonated soft drinks, sports drinks pasteurization, ice tea pasteurization.

- Brewery: Wort heater/cooler, condensate cooler, yeast cooler, beer cooler, pasteurization.

- Egg processing: Egg pasteurization, heating/cooling.

- Dairy: Raw milk cooling, milk pasteurization, yogurt cooling, ice mix pasteurization and cooling, cream pasteurization, cream/buttermilk cooling, cheese milk pasteurization, whey pasteurization.

- Fruit juice production: Juice pasteurization, juice concentrate cooling, water heating.

Technical specifications

- Working pressure: 10 - 25 bar

- Working temperature: -10 - 150 C°

- Connection sizes: DN25 - DN125

- Connections: DIN11853-1, DIN11864-2, DIN11851, ISO2852 Clamp

- Certification: PED, ASME U, CRN

- Construction: Designed according to 3A

Experience unparalleled quality and efficiency with Danfoss’s hygienic gasketed plate heat exchangers—your trusted partner in hygienic applications.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A world of heat exchangers | Romanian, Moldavian, Moldovan | Romania | 10 Oct, 2024 | 9.7 MB | |

| Brochure | A world of heat exchangers | Bulgarian | Bulgaria | 04 Oct, 2024 | 5.3 MB | |

| Brochure | A world of heat exchangers | English | Multiple | 15 Sep, 2025 | 4.7 MB | |

| Operating guide | DA - Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | DE - Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | EN - Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 02 Jun, 2025 | 9.6 MB | |

| Operating guide | FR - Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Brochure | Gasketed plate heat exchangers - Next-generation heat transfer solutions | English | Multiple | 15 Sep, 2025 | 5.6 MB | |

| Operating guide | HU - Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Brochure | Hygienic gasketed plate heat exchangers for the food and beverage industry | English | Multiple | 15 Sep, 2025 | 5.1 MB | |

| Operating guide | IT - Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | PL - Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | RU - Gasketed and semi-welded Plate type heat exchangers | Russian | Multiple | 17 May, 2024 | 16.5 MB | |

| Brochure | SONDEX® Free Flow sugar brochure | English | Multiple | 27 Nov, 2024 | 7.2 MB | |

| Brochure | SONDEX® Traditional Plate Heat Exchangers | English | Multiple | 12 Feb, 2024 | 9.4 MB | |

| Operating guide | SV - Gasketed and semi-welded Plate type heat exchangers | Swedish | Multiple | 17 Nov, 2025 | 9.6 MB | |

| Operating guide | ZH - Gasketed and semi-welded Plate type heat exchangers | Chinese | Multiple | 05 Jun, 2025 | 9.6 MB | |

| Brochure | Брошура_Вдосконалені рішення теплообміну | Ukrainian | Ukraine | 01 Oct, 2025 | 3.8 MB |

Related products

The performance and efficiency of the Brazed Plate Heat Exchanger (BPHE) have been proven through 30 years of constant development to ensuring high efficiency

Save time and money with MCHE standard products. The introduction of micro channel heat exchanger condensers, which combine resource and energy efficiency with minimal use of refrigerants, is enabling the development of leaner, greener solutions. Select one of our standard products and you can buy any quantity of condensers, any time, large or small, directly from stock.

The semi-welded plate heat exchangers are optimized for industrial applications. The semi-welded plate heat exchangers from Danfoss is designed for ammonia systems and can be used for applications such as Condensers, flooded and pumped evaporators, Sub-coolers, Desuperheaters and Oil coolers.

Exceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibers and solids, our SONDEX® Spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids. The design allows for a countercurrent flow that makes it possible to achieve very close temperature approaches.

SONDEX® Traditional plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have the largest plate portfolio in the world, and customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.

Our service team offers repairs, trouble shooting, upgrades, and on-site cleaning and maintenance of your plate heat exchanger solution. We always utilize genuine spare parts both for SONDEX® heat exchangers and our selection of other heat exchanger brands.

Gasketed plate heat exchanger service