Due to its geographical location, town of Kraśnik and its places of worship had been exposed to enemy assaults (Tartars; Cossacks /1648/, Swedes /1657/) since the very beginning of its existence. The wooden St. Paul’s church burned in early 15th century. After several years, a brickwork temple was built in the same location. At a later time, Jan Rabsztyński-Tęczyński started extension work which was accomplished in 1468. The Tęczyński-Rabsztyński family built a brickwork cloister on an L-plan and extended the parish church further by adding two chapels. Initially Gothic in style, the church obtained some Renaissance design features. At present, the renovated and well-kept church is a religious life centre for the town and region. Kraśnik is a deaconate seat.

Discovering the history

A major rafter framing overhaul was carried out in the period 1980-1983. Roofs of both the church and the bell tower were lined with copper sheet. The interior was renovated: stuccos of a great value were discovered, tombstones renovated under supervision of the Province Conservation Officer. In 1996 a computer-controlled clock and bells system were installed in the tower. Poland’s EU accession gave new financing options for investment projects. Further modernization works for the church (renamed to the Holy Virgin Ascension) commenced in 2007. Conservation officers started from the exterior facade and the sacristy interior. Plaster was removed to expose beautifully cut limestone – the basic church structure material. Interior works commenced 2009. The Conservation Officer gave permission for a floor exchange and a floor heating system installation.

The previous heating system consisted in old gas-fuelled boilers and air heaters, which made a destructive impact on the antique church interior and held a significant position in the parish budget. It was just that moment that the church management and the heating contractor made the decision: let’s try to use renewable energy for floor heating. “That’s the way heat pumps provide heating in Sweden. Why shouldn’t it work in our town?”, says Jerzy Zamorski, the parish priest, advocating the idea. “We’ve decided for collaboration with Ciepłotech company as having many years’ experience in updating heating systems for religious objects.”– he continues.

Photo: Church and cloister (left) and church seen from the clock tower (right)

The lower source – easy to say, more difficult to do

A low-temperature heating system, which means: a floor hearing system, is a perfect solution for churches and other similar objects as well as for heat pumps that deliver energy from renewable sources. Nevertheless, it should be stressed that, in normal conditions, the comfort temperature is approx. 20-22°C, whereas, for a church, this temperature is approx. 10- 12°C. Therefore, this situation is even more of benefit from both energy and finance points of view.

The starting point for a heat pump installation is, first of all, the ground source well, which should be correctly prepared. Within the parish ground lot, fifteen drills were made, each 100 m deep. Pipes were laid to the boiler room fitted with heat pumps.

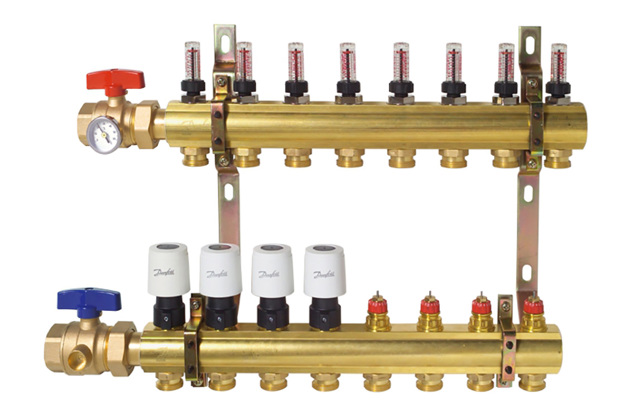

The boiler room is located in the ex-cloister building basement. All pipes were connected to a single manifold. “It took us 3 weeks to make all the drills, but the manifold access was a real surprise. We hoped to make the connection within 2-4 days. Actually, making 30 holes in the 2-metre thick old foundation wall required as long as two weeks.” - Mr. Roman Wysoczański from GeoWir company (responsible for the ground source preparation) says. “That has been the largest hydraulically balanced manifold in our history” Mr. Wysoczański adds.

Stage 1 included providing the boiler room with two brine/water DHP-L heat pumps, 12 kW capacity each. The pumps provide heating for the church, whilst in summer they will deliver hot water.

One could consider 24 kW to be insufficient for object of that size. Please note that the heat demand varies depending on the external air temperature, whilst alculation temperature values do not occur frequently. The cost-efficient solution consists in operating correctly-selected heat pumps as well as electric heaters used for peak demand periods. In the final settlement, that solution is optimal from both investment and operation points of views. The total system capacity is 42 kW.

Photo: Mr. Roman Wysoczański showing the ground source manifold (left) and Mr. Karol Sawicz presenting the DHP-L 12 kW heat pumps (right)

Heat distribution full with surprises

Heat is delivered by heat pumps from the lower source to the church and then over the floor heating loops to the heated rooms. The ex-cloister building is located approx. 30 meters from the church.

“While laying the heat transport pipes to the church, we had to improvise and modify pipe route plans many times. The church is very old, it underwent numerous overhauls and modernizations with not a single document left.” – Mr. Karol Sawicz from Ciepłotech says. The heat transport system is of a total of 160 meters of insulated pipes that deliver heat to five manifolds located inside pillars. From manifolds, heat is distributed over twenty five loops. The water temperature at loop inlet amount to 32°C. Two 20 kW gas-fuelled heaters were replaced with heat pumps of total capacity of 42 kW. Besides, the system operates in the “low parameter” mode, which allows achieving a high effectiveness grade of COP = 4.2. Finally, the parish will have lower heating costs. Stage two will include the boiler room extension; remaining heat pumps will deliver heat and hot water to the ex-cloister and administration buildings.

“Heavenly peace”

The Holy Virgin Ascension parish in Kraśnik includes an antique church and an ex-cloister building. Totally, nearly 1,800 sq. m and ten permanent residents are to be heated. Considering specific Poland’s climate, any heating system is a strategic investment. Besides, the church being a parish and a deaconate office, fulfills obligations towards the faithful.

At present, heat comfort is something normal during Holy Mass, religious education courses or meetings. For a majority of Polish parishes, church heating is among the largest budget items. Prior to the modernization, when the church was heated with gas, its consumption amounted to approx. 16,000 cu. m. For the period of December 2009 – March 2010, the electricity meter (for the heat pumps) indicated 7,000 kWh.

“Converting this to the money values: before, energy costs were approx. PLN 30,000. After the heat pumps and heating system had been installed, we paid only PLN 3,500. This is a really significant saving.” - Father Zamorski says, and adds: “For us equally important is the fact, that the heating does not adversely affect the antique interior. What’s more - we emit a smaller volume of hazardous substances. And this is a zero-maintenance system, therefore, we can concentrate on our religious duties and parish activities.”

Photo: Church interior, floor heating loop (left) and Father Jerzy Zamorski (right)

Facts

Location: Kraśnik, Lubelskie province

Investor: the Holy Virgin Ascension parish Parafia Wniebowstąpienia N.M.P.

Design and work: Ciepłotech

Church floor area: 600 sq. m.

Renewable energy sources: Two ground heat pumps DHP-L (12 kW)

Heat receivers: Floor heating system

Construction type: modernisation, 2009.

The heating system investment was financed from EU funds at disposal of the Narodowy Fundusz Ochrony Środowiska (National Environment Protection Fund) and from offerings.

Related products

-

if (isSmallPicture) {

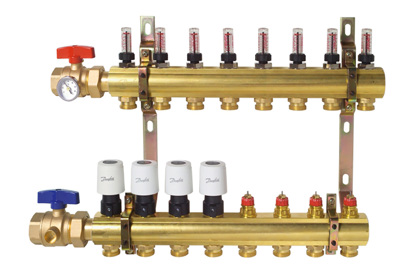

Manifolds and actuators

Manifolds and actuatorsDanfoss floor heating manifolds are characterized by their flexibility to establish the best suited manifold solution based on requirements. Select from all the components to construct a manifold with or without pre-setting, flow-meters, shut-off valves and air-vents that best fits your project.

-

if (isSmallPicture) {

Room controls

Room controlsTo ensure hydronic (water based) underfloor heating or cooling systems achieve the expected high level of comfort and low energy consumption, good room temperature controls are essential. They control the room or floor temperature to avoid overheating. For optimal comfort each room has it's own room thermostat.

-

if (isSmallPicture) {

Mixing shunts

Mixing shuntsDanfoss floor heating mixing shunts establish a water temperature low enough to safely be distributed through the floor heating system. It’s designed to fit the FH manifolds and mixes the warm supply temperature with colder floor heating return flow to the required floor heating supply temperature.