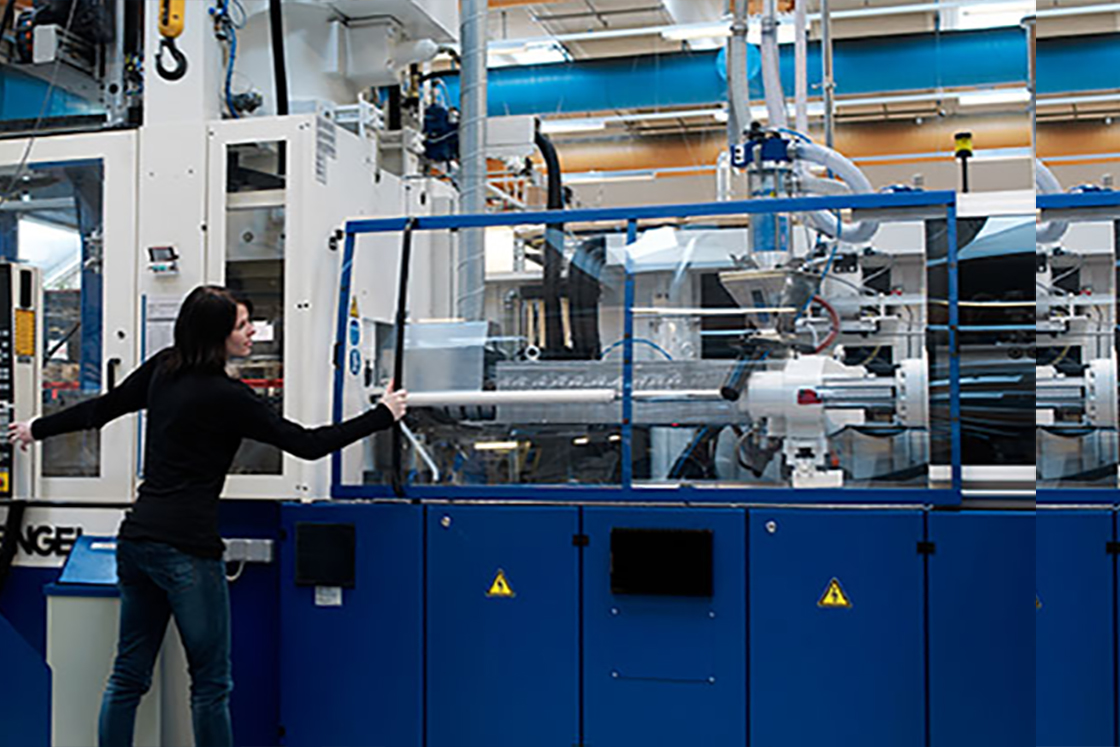

Tailored to the specific requirements of the plastics industry

The MBS 1600/1650 pressure transmitter is tailored to the specific requirements of the plastics industry. The high-quality and EMC-immune pressure transmitter comes in two versions:

- MBS 1600 – without integrated pulse-snubber

- MBS 1650 – with integrated pulse-snubber

View the 3D models:

The integrated pulse-snubber offers a high degree of protection against cavitation and liquid hammer. The fully welded and compact design provides excellent vibration stability and exceptional robustness. MBS 1600/1650 is 100 % immune to VFD-induced electric noise and noise from other direct-coupled electrical fast transients from valves and relays.

Features and benefits

Tailored for use in plastic processing applications

100 % immune to electric noise from VFD and other direct-coupled electrical fast transients from valves and relays

High burst and over pressure capabilities due to fully welded design

Protected against cavitation and liquid hammering

Fast time constant to support industry requirement (< 1 m sec 10 to 90% step response)

Wide operating temperature range (-40 to 125 °C)

Fully welded design and wetted parts made of stainless steel

Vibration and shock stability due to the ridged design

Zero drift due to excellent long term stability

Wide range of electrical and pressure connections

All absolute voltage output signals: 0 – 5 V, 1 – 5 V, 1 – 6 V, 0 – 10 V

Electrical noise

It can cause lost production hours, material waste and ultimately expensive damage and repair of machinery, if electric noise interferes with your plastic molding machinery. See how to avoid this.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | MBS 1600 For Industrial Hydraulic | English | Multiple | 07 Jan, 2022 | 6.8 MB | |

| Data sheet | OEM transmitters for heavy-duty applications, MBS 1600 and MBS 1650 | Chinese (CN) | Multiple | 22 Jul, 2020 | 589.4 KB | |

| Data sheet | OEM transmitters for heavy-duty applications, MBS 1600 and MBS 1650 | Italian | Multiple | 22 Jul, 2020 | 527.8 KB | |

| Data sheet | OEM transmitters for heavy-duty applications, MBS 1600 and MBS 1650 | French | Multiple | 22 Jul, 2020 | 520.6 KB | |

| Data sheet | OEM transmitters for heavy-duty applications, MBS 1600 and MBS 1650 | Spanish, Castilian | Multiple | 22 Jul, 2020 | 521.7 KB | |

| Data sheet | OEM transmitters for heavy-duty applications, MBS 1600 and MBS 1650 | Danish | Multiple | 22 Jul, 2020 | 519.3 KB | |

| Data sheet | OEM transmitters for heavy-duty applications, MBS 1600 and MBS 1650 | English | Multiple | 22 Jul, 2020 | 517.5 KB | |

| Data sheet | OEM transmitters for heavy-duty applications, MBS 1600 and MBS 1650 | German | Multiple | 22 Jul, 2020 | 554.6 KB |

Approvals

CE

RoHs

UL

Approval Certificates

Related solutions

-

if (isSmallPicture) {

Industrial hydraulics

Industrial hydraulicsVersatile and high-performance monitoring and control components for industrial hydraulics is what you will in the Danfoss Industrial Automation product portfolio.