Powering the future of energy-efficient brine mining

From seawater desalination to high-salinity brine concentration, Danfoss APP pumps and iSave energy recovery devices deliver the performance and energy efficiency needed to enable the next generation of mineral and salt recovery systems.

Why brine mining needs more energy-efficient solutions

As global demand for lithium, magnesium, and food-grade salt surges, brine mining is emerging as a less environmentally disruptive alternative to conventional mining. But brine valorization is only economically viable if energy use and system complexity are kept in check.

Danfoss APP pumps and iSave ERDs form the foundation of ultra-energy-efficient SWRO and OARO systems. They deliver the precise, stable high-pressure performance needed to make brine valorization commercially and environmentally feasible.

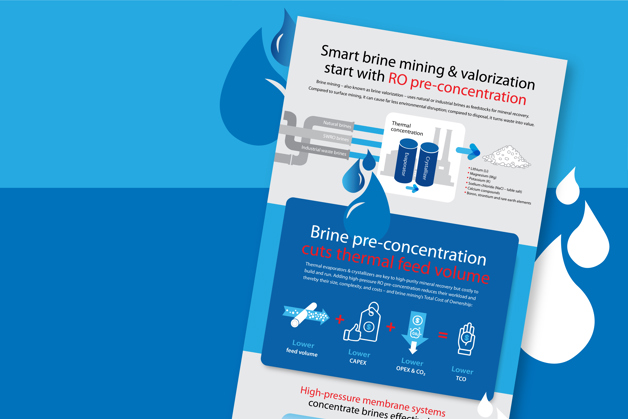

Learn how RO and OARO pre-concentration boost efficiency and cut brine mining's financial and environmental costs.

See infographic

Brine mining systems that integrate seawater desalination (SWRO) and osmotically assisted reverse osmosis (OARO) need precise, dynamic pressure control across high-salinity stages. Few pump technologies meet both the high-pressure demands of SWRO and the variable pressure needs of OARO while maintaining energy efficiency and reliability.

Danfoss APP pumps are designed for this challenge. As positive displacement pumps, they provide consistent flow and pressure regardless of system changes.

With up to 91.6% efficiency, they reduce specific energy consumption (SEC) and improve OPEX. Built from corrosion-resistant materials with a simple, serviceable design, APP pumps suit harsh, remote environments. Their modularity and VFD compatibility ensure precise pressure control and responsiveness in complex, multi-stage systems.

Read the full article here

Hyrec’s food-grade salt facility in Indonesia is the world’s first large-scale brine mining plant to integrate both SWRO and OARO membrane technologies. At the heart of this innovation are Danfoss APP pumps and iSave energy recovery devices, which enable high-efficiency brine concentration while minimizing thermal system demands.

Producing 220,000 tons of high-purity salt and over 27,000 cubic meters of desalinated water daily, the plant delivers exceptional output with low energy use and reduced environmental impact. Danfoss technology plays a central role in keeping system performance stable, even under shifting salinity and viscosity conditions.

“These high-pressure stages are critical to the plant’s TCO,” explains Hyrec’s Ata Kayaoglu, “and Danfoss technology ensures their energy efficiency, reliability, and adaptability.”

Read the full case story here

Rethinking brine mining with high-efficiency RO pre-concentration

Membrane-based pre-concentration is transforming how we recover resources from brine. Advanced RO and OARO systems are now enabling a new generation of brine valorization projects – ones that are smaller, faster to deploy, and far more energy-efficient.

By reducing the size and energy burden of thermal systems like evaporators and crystallizers, these high-efficiency membrane systems are making previously uneconomic brines viable. But membranes alone aren't enough – performance hinges on precision-engineered components like Danfoss APP pumps and iSave ERDs, which consistently minimize specific energy consumption (SEC) even at TDS levels above 150,000 mg/L.

Energy-efficient pre-concentration of brines is critical to unlocking circular resource strategies – and the same processes can help SWRO operators embrace the shift from brine disposal to brine valorization.

Explore how smarter hydraulic design is redefining what’s possible in mineral recovery.

Read the article

FAQ

What is brine mining (also called brine valorization)?

Brine mining, also referred to as brine valorization, is the process of extracting valuable minerals and salts from highly saline water sources. These sources include geothermal fluids, inland salt lakes, oil and gas wastewater, seawater, SWRO brine reject, and industrial effluents.

Instead of physically mining solid ores, brine mining is a process of separating water from dissolved minerals, often through multiple concentration staages. Once the brine is sufficiently concentrated, specific minerals like lithium, potassium, magnesium, or salts can be selectively recovered.

Watch Amogh Sharma answering the question: “What is brine mining (also called brine valorization)?”

Which minerals can be recovered through brine mining?

Brine mining enables the extraction of a variety of minerals, including:

- Lithium, critical for battery production

- Potassium and magnesium, used in agriculture and industry

- Bromine, used in flame retardants and pharmaceuticals

- Sodium chloride in the form of industrial or food-grade salts

- Other trace elements like boron, rubidium, and cesium

What are the main stages in the brine mining process?

Brine mining generally follows this process chain:

- Extraction: Brine is pumped from subsurface reservoirs, geothermal wells, seawater, or captured as an industrial byproduct

- Pre-treatment: Solids, organics, or scale-forming compounds are removed to protect downstream equipment

- Pre-concentration: This reduces water content to increase mineral concentrations; technologies include membrane-based and thermal processes

- Final concentration and recovery: Typically involves thermal technologies like evaporators and crystallizers, where solids are precipitated and extracted

- Post-treatment: Includes handling of residual brine or waste, water reuse, or reinjection

Watch Georg Herborg answering the question: “What are the main stages in the brine mining process?”

What are the main technologies used for pre-concentration?

Brine mining depends on both membrane and thermal pre-concentration technologies:

Membrane:

- Reverse osmosis (RO)

- Osmotic-assisted RO (OARO)

- Nanofiltration (NF)

- Forward osmosis (FO)

Membrane-based technologies are more energy-efficient than thermal and are well-suited for reducing water volume before thermal processing.

Thermal:

- Multi-effect distillation (MED)

- Mechanical e(MVC)

- Vacuum Evaporation

More energy-intensive, thermal-based technologies are effective at higher concentrations.

What role does Danfoss play in brine mining, and what technologies do you offer?

Danfoss provides a modular, high-efficiency platform of components tailored to the unique demands of high-pressure membrane processes in brine mining – particularly in pre-concentration stages using technologies like reverse osmosis (RO) and osmotic-assisted RO (OARO).

Our core technologies comprise:

- APP high-pressure pumps

Danfoss APP axial piston pumps are positive displacement pumps designed for consistent high efficiency across a wide operating range. Unlike centrifugal pumps, which lose efficiency when operating away from their best efficiency point, APP pumps maintain over 91% efficiency even as pressure and flow requirements change. This makes them ideal for brine mining systems using both SWRO and OARO pre-concentration, where operating conditions can vary from stage to stage. Operators can adjust flow and pressure with no efficiency penalty. The result is a single, flexible pump platform that simplifies system design and maximizes energy savings. - iSave and MPE70 ERDs

The iSave and MPE70 isobaric energy recovery devices go beyond pressure recovery. In addition to reducing pump load and energy use with outstanding efficiency, they also provide active control over pressure and mixing, a key advantage in processes like OARO, where controlled brine blending lowers osmotic pressure and improves membrane performance. Unlike passive ERDs, active ERDs integrate pressure exchangers and booster pump for real-time process control. Proven at Hyrec’s brine mining plant in Indonesia, where iSave ERDs operate at over 93% efficiency while reducing energy consumption, extending membrane life, and stabilizing system performance under fluctuating conditions.

Together, Danfoss APP pumps and active ERDs form a flexible, energy-efficient platform for membrane-driven brine concentration systems. They support higher recovery rates, greater system uptime, and improved environmental performance – all of which are essential as the industry moves toward more sustainable, scalable brine mining solutions.

Additionally, Danfoss provides application and co-innovation support, working closely with plant designers and system integrators to optimize performance and adapt to specific brine chemistries. Danfoss solutions are found in several pilot and commercial installations, including the Hyrec brine mining plant in Indonesia for the production of food-grade salt.

What are the main challenges in developing a brine mining project?

Brine mining comes with a unique set of technical, economic, and environmental challenges:

- Energy consumption: Concentrating brine, especially in thermal stages, is energy-intensive. Membrane rather than thermal pre-concentration can reduce total energy use

- Operating costs: Energy, chemicals, and maintenance costs must be tightly managed

- CO₂ footprint: Projects relying fully on thermal methods tend to have higher emissions unless powered by renewables

- Brine variability: The composition of brine sources varies widely, requiring customized process design

- Scaling and fouling: Minerals can precipitate inside equipment, reducing efficiency and increasing downtime

- Waste brine and discharge: Must be treated or managed carefully to minimize environmental harm

Is brine mining economically viable?

Yes, brine mining is increasingly viable, not least for minerals like lithium, where global demand is rising rapidly, but also for the production of food-grade salt at scale as well as potassium, magnesium, and bromine. Key factors influencing the business case include:

- Mineral market prices

- Concentration levels in brine

- Technology mix (membrane vs thermal)

- Energy costs and availability

- Plant reliability and scalability

Is there a future in mining minerals from seawater reverse osmosis (SWRO) reject brine?

Yes, this is a developing area of interest. SWRO reject brine, the concentrated waste stream from seawater desalination, contains valuable elements like lithium, magnesium, and boron.

While currently underutilized, several pilot projects are exploring the valorization of SWRO reject as a secondary mineral resource. As desalination expands globally, so too does the potential to turn this waste stream into a feedstock for low-impact brine mining.

What are the growth trends in brine mining?

Brine mining is a rapidly growing segment of the mineral extraction industry, driven by:

- Surging demand for battery minerals, especially lithium

- Global interest in mining alternatives with lower environmental impact

- Expansion of ZLD regulations, especially in water-stressed regions

- Technological advances in high-pressure membrane systems, automation, and system integration, that reduce total cost of ownership (TCO)

- Greater availability of industrial brines from geothermal, oil and gas, and desalination

Read more about solutions for desalination

Related applications

Due to high energy efficiency and reliability, Sea Water Reverse Osmosis (SWRO) is one of the most sustainable and cost effective solutions for converting sea water to potable fresh water. Danfoss is committed to supporting the desalination industry with energy efficient SWRO solutions.

Contact us

Maximize energy efficiency

Danfoss provides sustainable solutions for a range of applications to boost energy efficiency, reduce costs, and lower emissions. Reach out to our experts to discover how we can help you achieve these goals.

Get in touch with sales

Follow us to stay up to date with the latest news, updates, announcements, and resources from High Pressure Pumps. Of course, we want to hear from you too - so jump in and join the conversation.