Reduced installation and running costs in chillers

Core component of the HVAC system, a chiller cools the water or brine used to cool and dehumidify air in buildings or industrial processes. It's a factory-assembled unit that cools the water or brine using an evaporator, and has an internal or a remote condenser with appropriate controls. The condenser can be either water-cooled or air-cooled. A chiller based on such a design has a variety of applications, from space cooling to process purposes.

A typical modular chiller unit uses tandem fixed-speed compressors to provide some part-load capability for the modular system. These units share the same water system to provide cooled or heated water to the building.

Danfoss offers the option of using only one variable speed compressor instead of a fixed-speed tandem in order to better match the capacity requirement of the modular chiller unit.

Why choose Danfoss variable speed compressors for modular chillers?

For the end user:

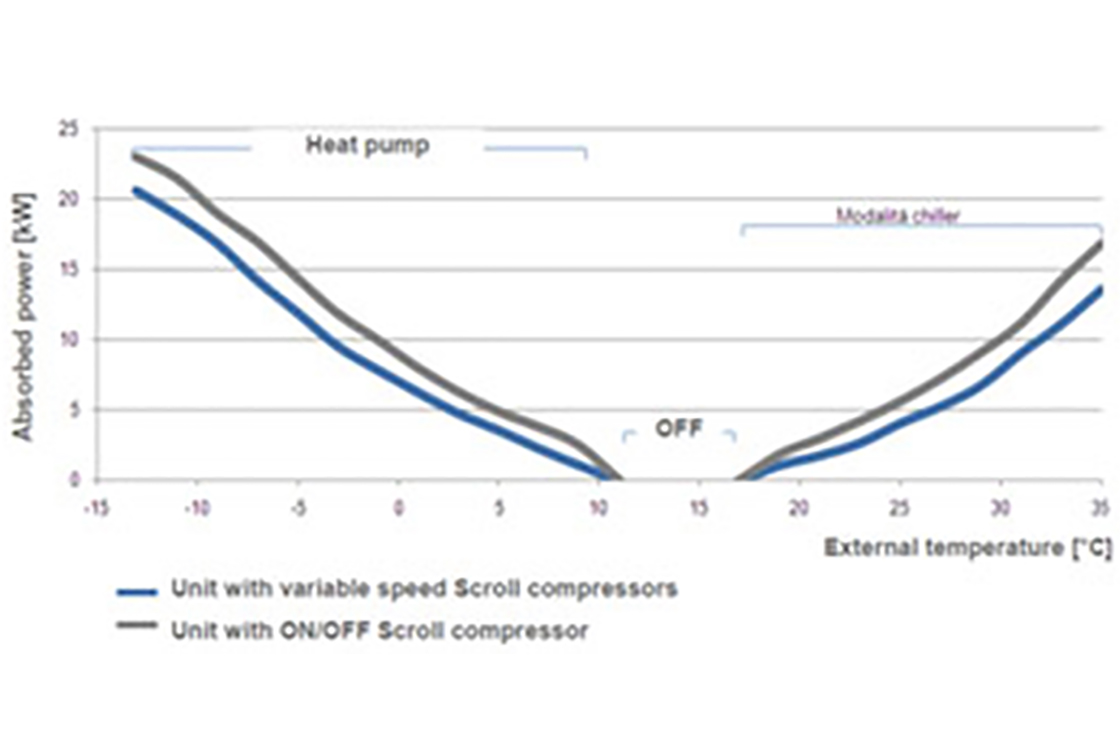

- Using the Danfoss inverter compressor solution, the unit will have much better seasonal energy efficiency, providing energy savings all year round. The energy saving potential in both heating and cooling modes is illustrated in the graph below as a function of ambient temperature:

For the OEM:

- By using one inverter compressor, the design of the unit can be simplified to provide continuous capacity output over the full speed range. The manufacturer can provide flexible options to the end user such as:

- Full variable speed solution, where all units use variable speed compressors to achieve the best efficiency and modulation.

- A solution using a combination of variable-speed compressors with other fixed-speed compressor modules, allows a good improvement in energy efficiency whilst remaining cost competitive.

- Cost reductions can be achieved because fewer components may be needed, such as multiple fixed-speed compressors, relays, and pressure switches; the amount of piping required will also be less.

- Modular chiller units using Danfoss variable speed compressor solutions also provide the opportunity for manufacturers to offer an alternative to VRF units.

- VZH variable speed chiller designs also give manufacturers the opportunity to offer innovative and differentiated solutions which can improve product and brand image, instead of units using traditional on-off compressor technology.

What other benefits are there for your customers when they choose Danfoss inverter compressors?

- Reduced installation costs: thanks to the more reactive adaptation to cooling demand, the manufacturer or the installer has the possibility of eliminating or downsizing buffer water tanks, with a significant cost saving and reduction in footprint

- Lower sound level: under part-load conditions, especially during the night, chillers using a variable speed solution will have lower sound levels than traditional on-off compressor systems in both running and start-up periods

- Short pay-back period: the pay-back period with this innovative technology can also be as little as 2 years for the end customer

- Lower environmental impact: reduced impact on the environment with R410A refrigerant

The most important benefits for customers

- Energy savings

- Reduced installation costs

Highlighted products

Something went wrong. We are working on this. Please, try again a bit later.

Case studies

Something went wrong. We are working on this. Please, try again a bit later.

Contact us

For further information, please contact us.