As food retailers look to reduce energy bills, every incremental savings counts. Increasing price competition means operating costs have an immediate impact on competitiveness and profitability—and, after staff, energy is the biggest bill most supermarkets have.

In food retail, most of that energy is spent on refrigeration, so efficient new components, like the AKVP electric expansion valve and high-end case controllers, are usually a good investment.

For example, a robust minimum stable super-heat algorithm — which ensures the evaporator is always fully utilized under all conditions — can save 8-12% of energy use at the system level.

But this method requires several components to work together perfectly. And this introduces a broader challenge: each new advance in technology also makes a system more complex. This can mean it’s harder to install, service, and configure…unless you have help.

This is where today’s smart case controllers (also called control solutions) make the difference. As refrigeration technology gets more sophisticated, the best modern case controllers handle that complexity for you, optimizing efficiency and helping you make good decisions.

-

if (isSmallPicture) {

Case controls

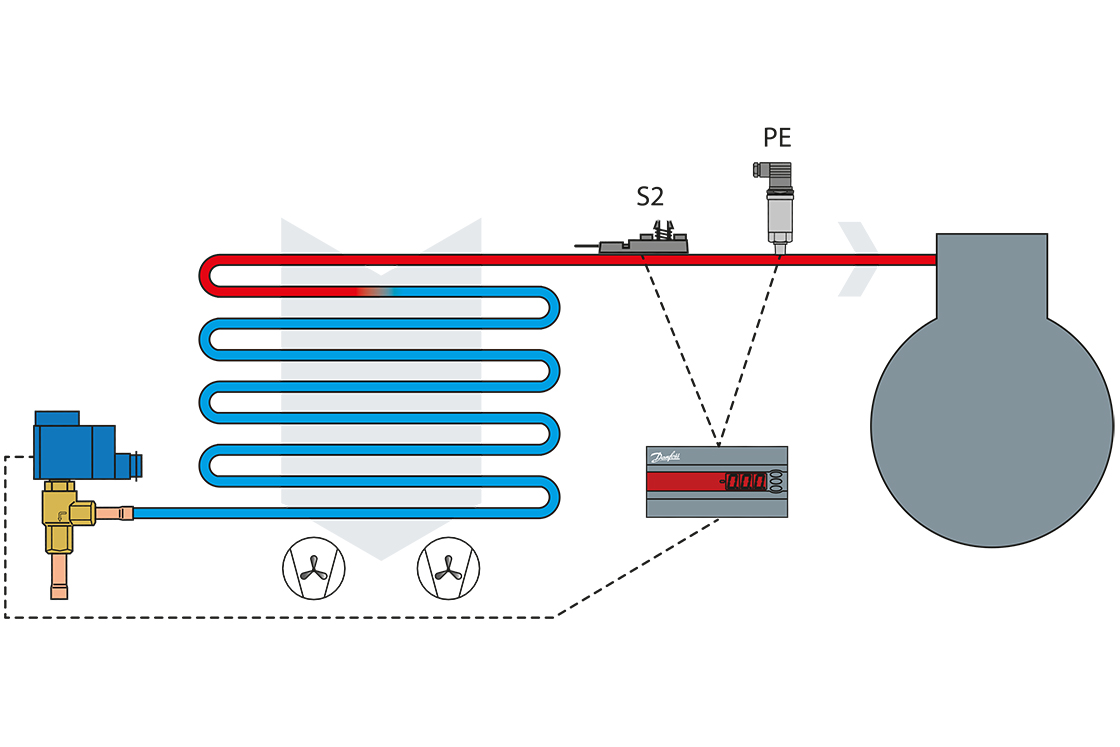

Case controlsYour refrigeration system is the natural place to look for energy efficiency gains. To unlock that potential, you need a controller, expansion valve, and high accuracy sensors that are smart enough to make the technology work together—and a system manager that can help you see and control the bigger picture.

-

if (isSmallPicture) {

HRU - Heat Recovery Unit

HRU - Heat Recovery UnitThe Heat Recovery Unit (HRU) is designed to recover the waste heat from C02 refrigeration installations. Recovered heat can be used for own heating purposes or returned to a District Heating Utility network.

-

if (isSmallPicture) {

Smart store

Smart storeThe Smart Store solution enhances food safety and brings down the energy bill by integrated and smart control of refrigeration, HVAC, lighting and other applications.