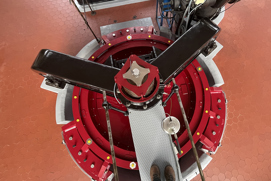

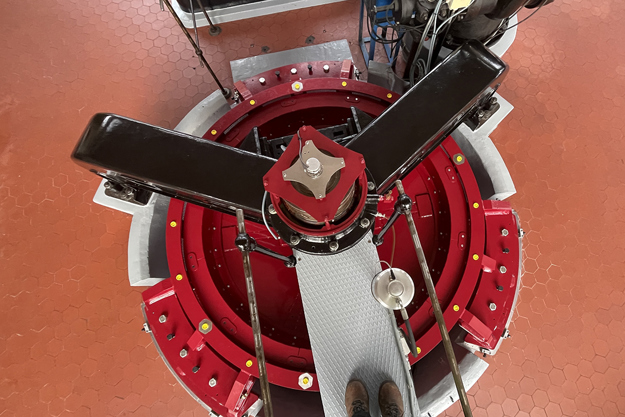

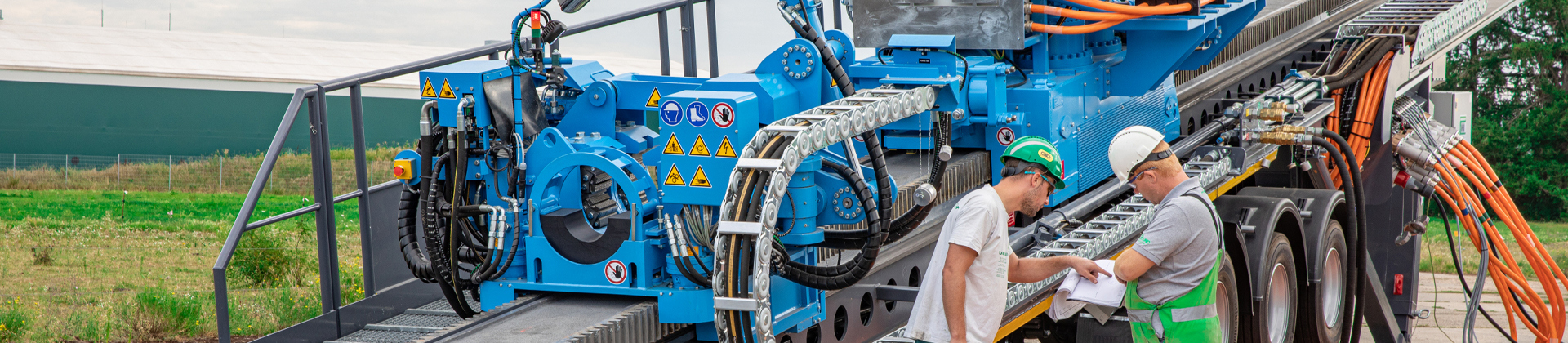

荷兰:由于建筑机械 每年占全球排放量的 1.1% 左右,因此实现减排的所有努力都至关重要。2022 年,在丹佛斯的支持下,Herrenknecht 能够调试新型电气化水平定向钻机。该钻机能够钻进高达 1,500 米的深度,需要高转矩精度,同时保持机动性。

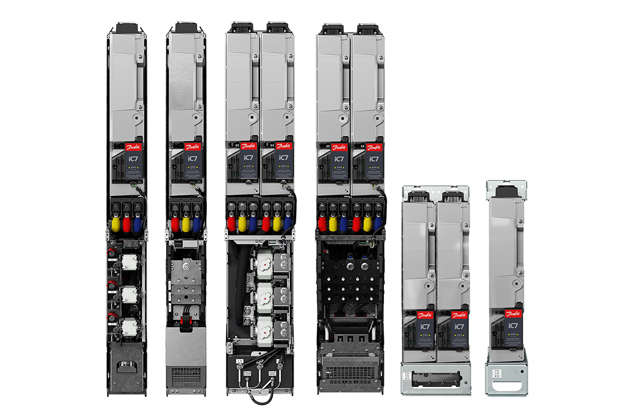

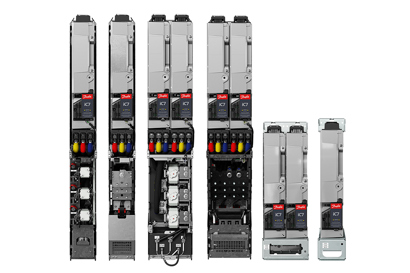

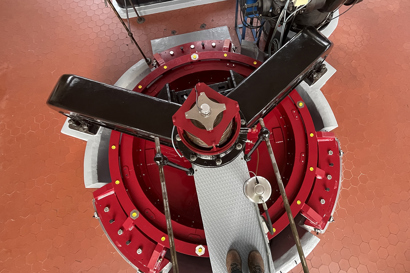

Herrenknecht 为其 HDD 钻机配备了丹佛斯 EDITRON EM-PMI 同步磁阻辅助永磁电机和 iC7-Automation 变频器,在不影响机动性的前提下获得了必要的功率。HDD 钻机现在不仅更节能,而且性能也比以前的液压系统更好。

继续阅读,了解 Herrenknecht 配备 EDITRON 电机和 iC7-Automation 变频器的 HDD 钻机电气化改造后的效果如何超出预期。

挑战:具有高性能的钻机机动性

施工现场面临脱碳压力,但由于电气化改造的机会尚未得到证实,因此仍然犹豫不决。为此,Herrenknecht 和 Danfoss 决心衡量并展示其先进技术的优势。

对于 Herrenknecht 的 HDD 钻机而言,机动性是一项基本功能,对尺寸和电源都有限制。由于电网仅提供 400V 交流电源,成功实现电气化需要高效的 AFE 系统来提升高速钻进操作的电压。

HDD 钻机对扭矩精度的要求特别高。为了保护齿轮和机械装置,系统必须能够应对在软软土地层或岩石中钻进时可能发生的快速转矩抖动。此外,消除惯性停车至关重要,因为减速后,钻杆会像弹簧一样被卷起。任何惯性停车会导致它们朝相反方向加速,从而可能造成钻杆的螺纹连接松动。相反,变频器必须在达到零速后缓慢降低转矩,以逐渐释放张力。

解决方案:高精度和前所未有的转矩控制

在为 HDD 钻机选择电机时,Herrenknecht 面临着在传统感应电机和更先进的 EDITRON EM-PMI SRPM 电机之间做出的选择。考虑到钻机的机动性要求,SRPM 电机设计紧凑、重量轻,与体积较大的感应电机相比,成为首选。此外,EDITRON 电机约 96% 的额定能耗以及精确的转矩和速度控制对于满足高性能需求至关重要,可同时提供能效和运行精度。

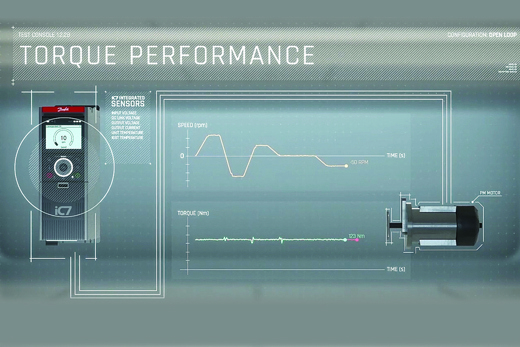

与 iC7-Automation 风冷式系统模块(可提供前所未有的转矩控制)配合使用,这些电机可以成功满足机动式水平钻机的严格要求。AFE 有效利用钻机的电势,将 400 V 交流电转换成 700 V 直流电,同时最大限度地减少谐波,使钻机充分利用电网电力。

iC7-Automation 变频器配备了独特的负载降低功能,可确保机械连接的电机之间的功率均匀分配,保护机械装置并保持稳定的性能。在此安装中,系统对高速设置范围内的六台连接永磁电机进行负载降速至零速,同时保持高转矩精度。

iC7-Automation 的优点

- 由于采用了新的原始控制算法,具有出色的低速性能

- 利用 0-370 Hz 频率调节实现高转矩精度

- 负载降低功能可提供均匀的功率分配和稳定的性能

- 能够通过 AFE 系统提升直流电压

- 紧凑型设计结合了高扭矩和高功率,最大限度地减少占用空间

- 标配安全转矩关断(STO SIL3)功能,以提高安全性

成果:用 400 伏交流电网供电产生 700 伏直流电

相关产品

-

if (isSmallPicture) {

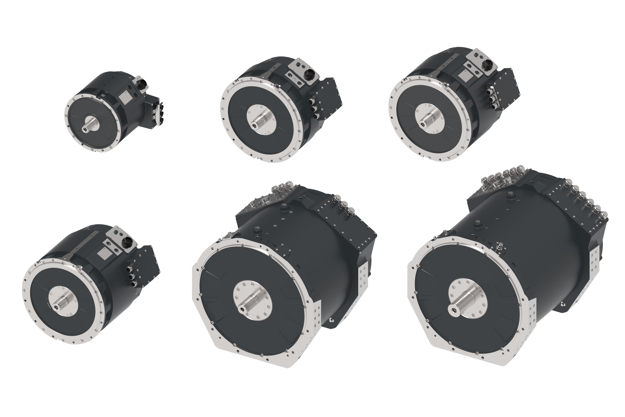

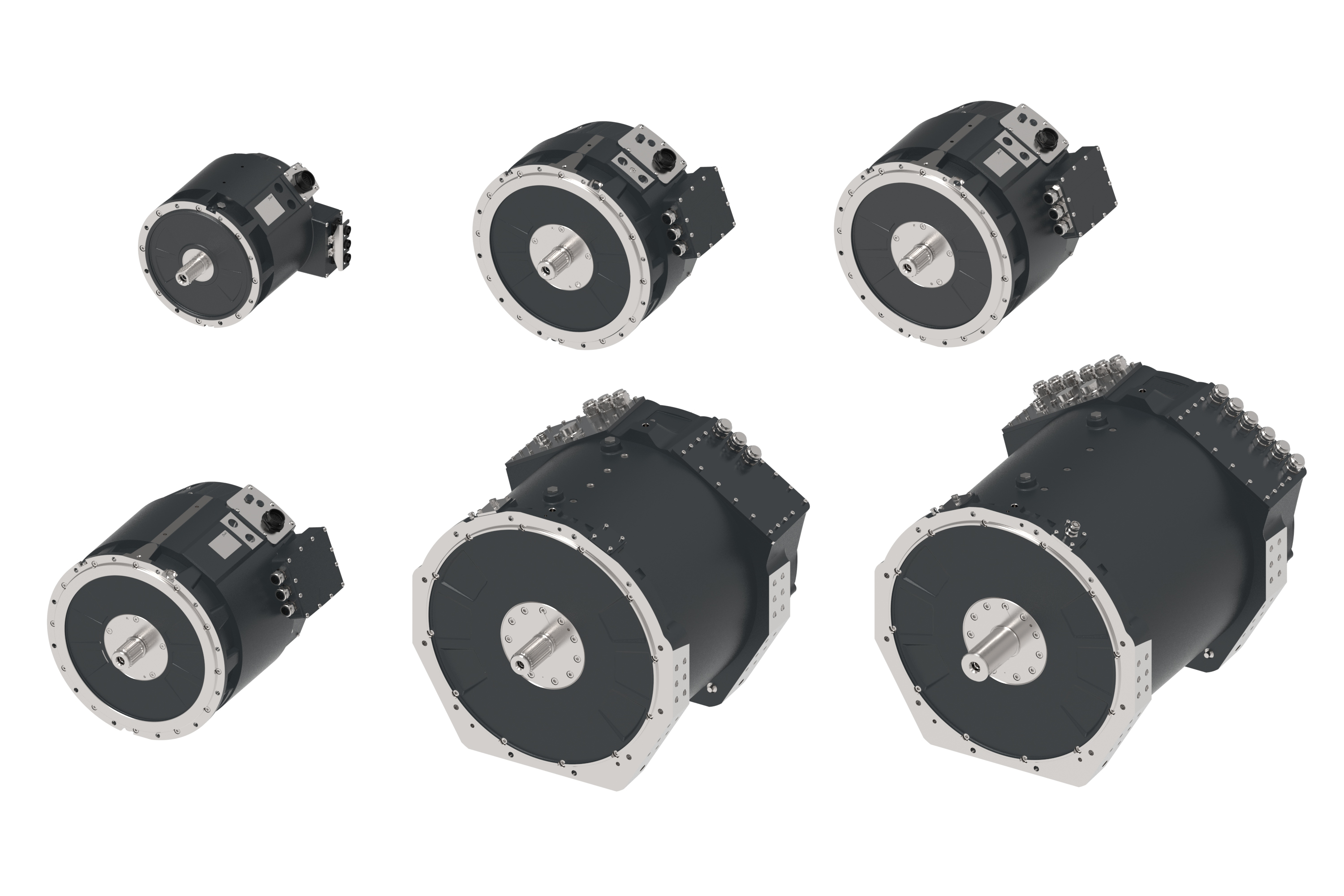

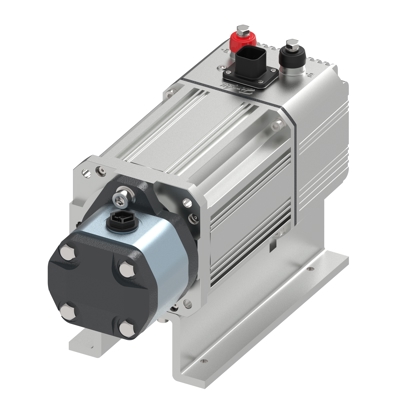

高压多用途马达

高压多用途马达各种电机允许根据所需的转矩、速度或功率选择确切的机器类型。高效,可在混合动力或全电动应用中实现更高的工作范围。所有电机均设计用于应对作业机械、商用车辆和船舶应用中的恶劣工况。

-

if (isSmallPicture) {

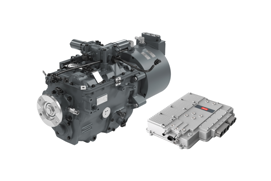

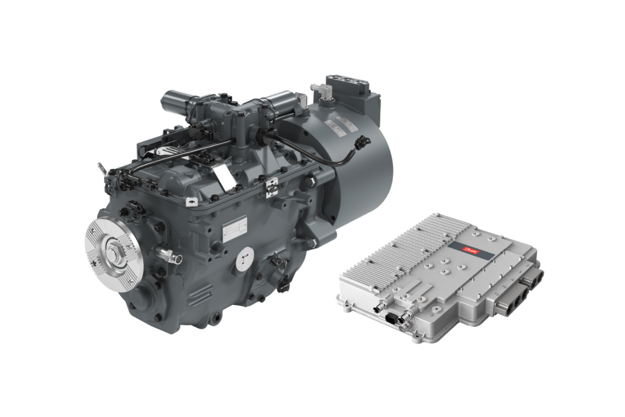

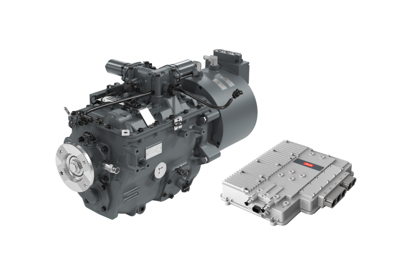

eDrivetrain 系统

eDrivetrain 系统eDrivetrain 系统是由高效电机、多速变速箱和牵引逆变器组成的一套全面解决方案。

-

if (isSmallPicture) {

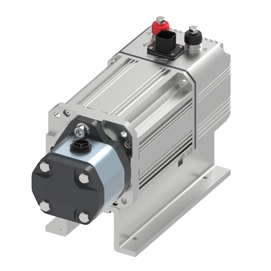

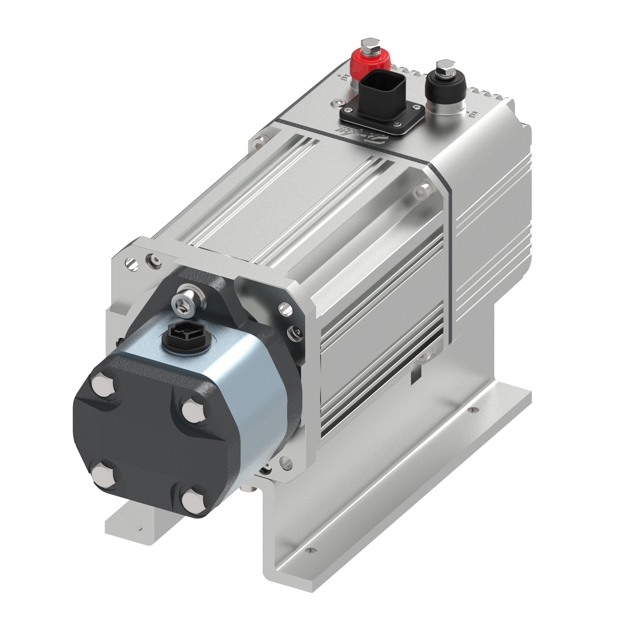

ePowerpack

ePowerpackePowerpack 包括高性能内部永磁马达和带有全功能数字信号处理器的高功率风冷变频器。

-

if (isSmallPicture) {

高压多用途马达

高压多用途马达各种电机允许根据所需的转矩、速度或功率选择确切的机器类型。高效,可在混合动力或全电动应用中实现更高的工作范围。所有电机均设计用于应对作业机械、商用车辆和船舶应用中的恶劣工况。

-

if (isSmallPicture) {

iC7-Hybrid

iC7-HybridiC7-Hybrid 变流器是您迈向能源转型的第一步。在船舶电力转换中利用混合动力和纯电力解决方案实现节能。加强能源存储、岸电、充电和电解等智能电网应用。

案例故事

-

if (isSmallPicture) {

捷克水力发电厂通过变频器改造提高效率

捷克水力发电厂通过变频器改造提高效率捷克:当 Albrechtice 水力发电厂用变速控制装置取代 80 年前的齿轮时,发电量增加了 10%。

-

if (isSmallPicture) {

丹佛斯为 SmartGrid 大容量储能系统提供动力

丹佛斯为 SmartGrid 大容量储能系统提供动力荷兰:SmartGrid 智能电池集装箱可在 8000 个循环后保持 80% 的容量,保证每天放电和充电且可持续 21 年,而不会出现性能问题。

-

if (isSmallPicture) {

QINOUS 储能优化了全球热电联产

QINOUS 储能优化了全球热电联产电气化和混合动力解决方案正在飞速发展。德国储能制造商 QINOUS GmbH 是很久以前开发这类解决方案的丹佛斯首批客户之一,此前这是能源行业的“热门话题”。

-

if (isSmallPicture) {

电气化和行业联合实现了 FlexHeat Nordhavn 的 CO₂ 目标

电气化和行业联合实现了 FlexHeat Nordhavn 的 CO₂ 目标丹麦: 位于哥本哈根诺德海文 (Nordhavn) 港口的 FlexHeat 区域供暖工厂每年排放的 CO₂ 比 LPG 气体替代方案少 315 吨。