Customer Profile:

Century Crane Engineers Private Limited is one of the top players in manufacturing and exporting a high-quality range of Material Handling Equipment and fabrication requirements over 25 years with a fully equipped manufacturing plant in Faridabad, India.

Their product portfolio consists of Material Handling Equipment, Material Handling Cranes, and Perforated Plates. The products are manufactured with the guidelines laid in the industry to attain the highest benchmarks in quality. In addition, long life, easy usage, high performance, and optimum quality are some of the highlighting features of our offered range of products.

The Challenge of Frequent Product Failures due to Power Fluctuations

The customer uses technologically advanced manufacturing equipment, state-of-the-art processing and packaging machinery, and the latest testing tools, which require resilient drives solutions for process efficiency and energy savings.

The frequent product failures due to the fluctuating power supply resulted in a loss of productivity. Also, there was lack of service support to mitigate the existing product failure scenarios, which resulted in higher downtime. So, the customer needed a solution to facilitate their futuristic manufacturing quality testing units to ensure the highest productivity and product quality to meet the industry quality standards.

The requirement for different voltage ranges of variable speed drives and their differentiations in the alignment was challenging, which led to a lack of expertise in servicing, unreliable operations, and programming difficulties.

Solution Offered:

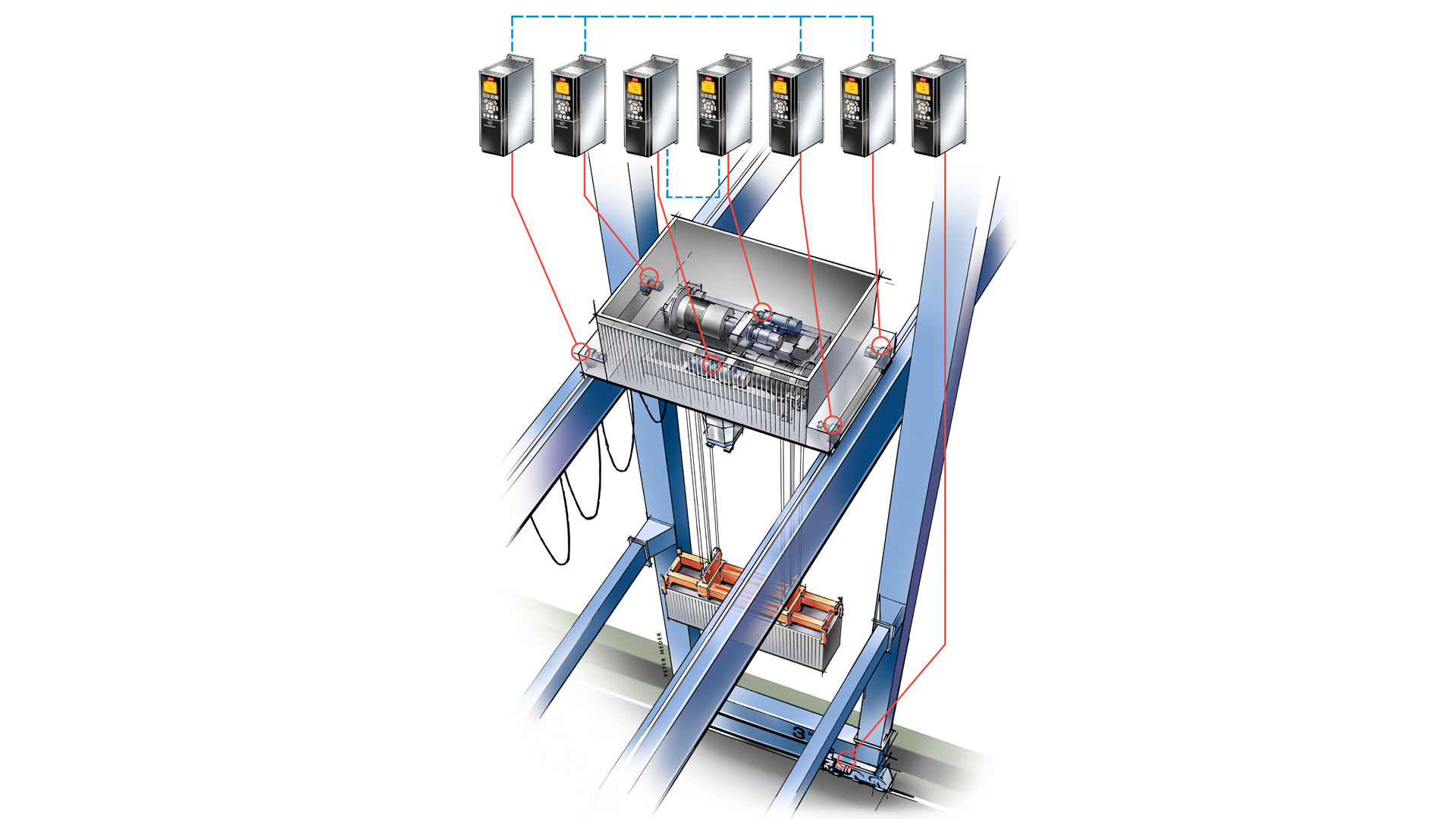

- Long Travel Capacity– Maximum motor 11KW MPM -20/30 (VFD-Model: FC-360)

- Cross Travel Capacity– Maximum motor 37KW/45KW MPM -15 (VFD-Model: FC-360)

- Main Hoist Capacity– Maximum motor 90KW/137KW for 230Tonn MPM -2/3 (VFD-Model: FC-360/ FC-302)

- Auxiliary Hoist Capacity– Maximum motor 45KW MPM -6 (VFD-Model: FC-360/ FC-302)

Drives are the key to Efficiency!

Today’s crane manufacturing processes are extremely complex, depending on the type and weight of the metal. The many different components that will later be assembled into cranes are made using a variety of metalworking equipment. Lathes, drills, and other precision machines are used to shape the steel as required. While performing, due to frequent product failures, the processes are stopped, hindering productivity and precision in manufacturing.

Danfoss Drive technology is the best engineering solution for the EOT (Electric overhead traveling) cranes to regulate the precision in the process through variable speed control and maintain a Zero-to-Nil failure ratio, which in turn improves productivity with superior quality.

Controlling the tension of the metal moving through the machine, VLT® ensures synchronized speed and maintains the quality of the crane and machine efficiency. An automated process is the key to efficiency, especially at high speeds. Active Front End modules are used as supply units enabling regenerative braking by feeding practically harmonic-free braking energy back into the supply.

Danfoss Drives are adapted with Crane specific features like the Integrated Crane Control Program to control the mechanical brake of the motor for more consistent and uniform motion control for load up/down movement, and reliable operation, with less wear & tear. The Drives interface is programmed for easy accessibility reducing the complexities in operation and maintenance.

The products were delivered on time by proactively aligning the product requirements and understanding the customer’s needs. This helped the team to be supportive across India with higher safety, and reliability.

Customer Quote

“Quality with great performance of the Danfoss VFDs, working precisely as per the requirement and it is hassle-free since December 2016. Easy commissioning and service support from Danfoss is much better than other VFD manufacturers. M/s Danfoss India Private Limited-service support creates benchmark w.r.t other suppliers. We wish them success and looking for long association with Century Cranes.”- Sachin Sharma, Director- Marketing, Century Crane Engineers Pvt. Ltd.