Step into a high performance, energy efficient & sustainable future

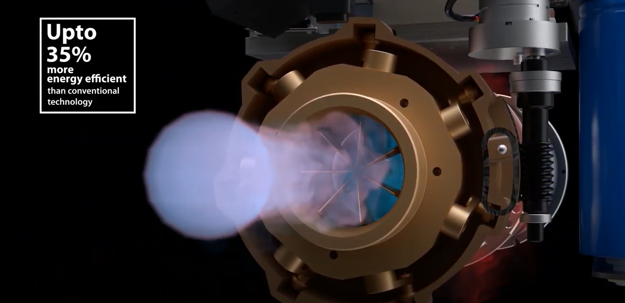

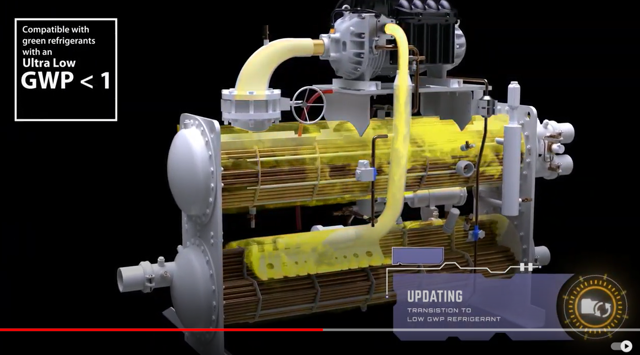

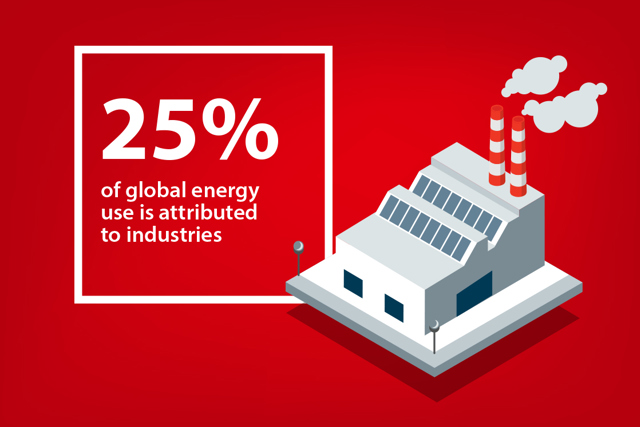

Climate change is real, and today’s HVAC system are expected to be stipulated as per the regulations demand to meet energy and performance efficiency. Danfoss Turbocor® compressor - the world’s first oil-free magnetic bearing compressor, is 35% more energy efficient than the conventional chiller.

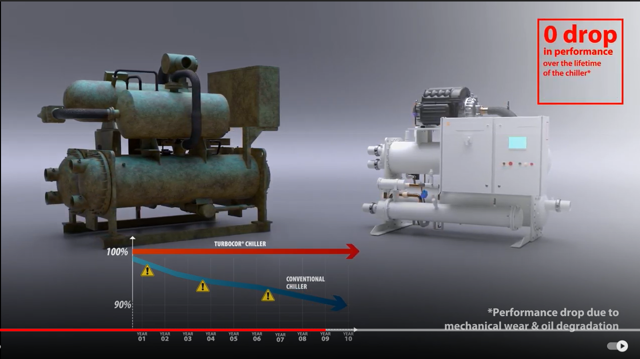

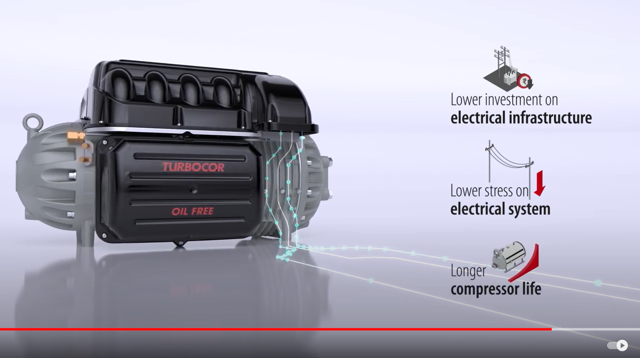

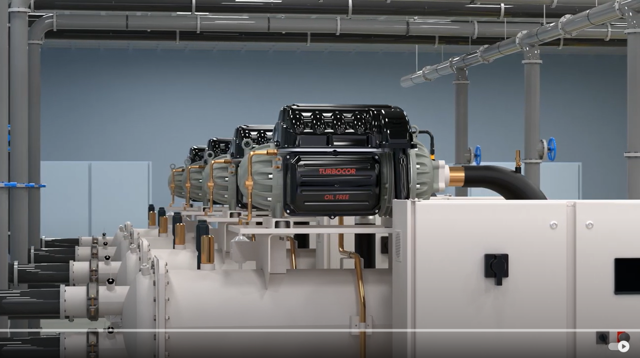

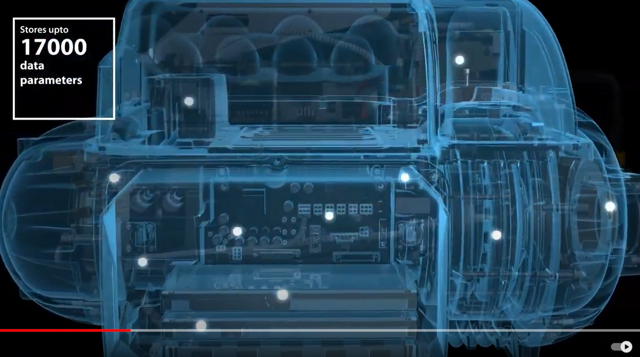

The future-ready oil free technology enables the HVAC professionals to design the system that can be upgraded as per the forthcoming regulatory norms. The magnetic bearing technology eliminates the need for an oil lubrication and further reduces the associated maintenance costs and increases the uptime of the chiller.

Magnetic Levitation Tech

Why the smart magnetic levitation technology?

Instead of why, let’s stick to why not! Here are your reasons to choose Turbocor, your HVAC engineers can enjoy the noise-free chiller plant rooms with no more hassle errands of oil lubrication. Friction-free magnetic bearings eliminate the cost of those inefficiencies and the maintenance costs associated with oil service. Hence less wear & tear and improved long service life. Our Magnetic bearings technology contributes to the most efficient, reliable, quiet, and low maintenance centrifugal compressors available in the market. Let’s get you the smartest Oil-free magnetic bearing compressor, all you to have to do is drop-in your details.

Benefits Proposition Blocks