Introduction:

In older commercial buildings, hydronic heating and cooling systems are among the most prevalent types of heating and cooling systems. The challenge related to the temperature control in these buildings is that they use air-based distribution systems for the heating solution, which decreases the indoor climate quality and the occupant comfort.

The air-based heating solutions in the old commercial buildings employ high volumes of air for energy transportation and distribution. This can lead to high noise levels from increased air volumes and velocities; also, the working environment is compromised, eventually reducing performance & productivity.

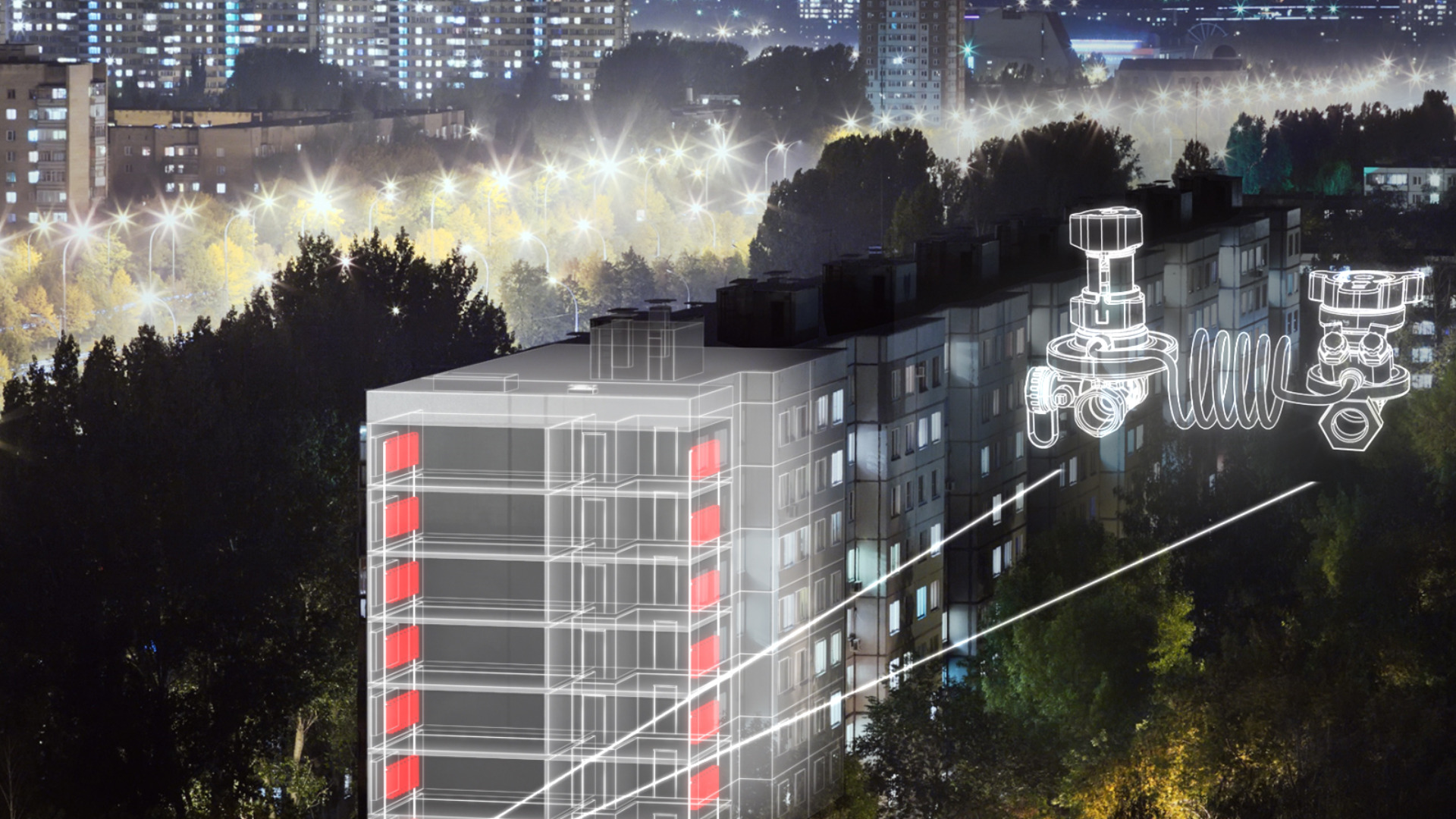

Danfoss modular hydronic HVAC 4.0 design solutions offer the highest energy efficiency for intelligent buildings. The digitalization of HVAC systems brings forward a wide range of possibilities, but since every building is unique, they pose different challenges. The Danfoss digital hydronics solutions provide an assortment of modular solutions to look after all your digital hydronic HVAC 4.0 design requirements.

Challenges faced by commercial buildings when using traditional hydronics HVAC systems and the advantages offered by Danfoss digital hydronics solutions to resolve them:

1. Pressure Independent balancing Control Valves (PICV)

Challenges: The traditional HVAC systems face complex valve sizing, hydronic balancing and system calculation-related issues. The fluctuations in temperature control can be seen; also, there can be overflows in the system due to the opening/closing of the valves. Furthermore, low delta T syndrome is also observed.

Advantages of using Danfoss PICV in temperature control systems: You can easily select the valve according to the design flow calculation. You benefit greatly from a single product's integrated balancing and control features. The dynamic balancing feature supports the design flows at partial and full load settings. The accurate temperature control solutions and high delta T support the concept of energy-efficient buildings.

2. Actuators

Challenges: In traditional temperature control systems, manual commissioning of the valves is required based on the design flow. In the case of calculation, mistakes or design changes at a later stage can result in complaints. The building management system (BMS) (wiring) integration is complicated, and there is a limited possibility of transparency in the building energy usage.

Advantages of using Danfoss NovoCon digital actuators in temperature control systems: These actuators support remote and mass uploading of flows related to design through the BMS or configuration tools. Furthermore, the corrections to these flows can be centrally carried out using the BMS. The NovoCon digital actuators employ standard BACnet or ModBus for carrying out bus communication and prefabricated cables for seamless BMS integration. These actuators also support complete transparency concerning energy consumption in the buildings for heating and cooling solutions.

3. Sensors

Challenges: There is limited visibility of the maintenance cost during the building's lifetime. Also, there are minimal statistics available on the poor performance of the room temperature control systems. The integration process of different sensors in the BMS is highly complex.

Advantages offered by using intelligent sensors in HVAC 4.0 systems: The flow and temperature sensors can be directly connected with the NovoCon actuator. You can get highly accurate and valuable insights related to the functioning of the HVAC system of your installations. These intelligent sensors capture the energy flows in the building based on the air handling unit and the terminal unit; this helps in the advanced transparency of energy flows. Using these sensors, you can carry out predictive maintenance of data and transparency (in terms of lifetime usage, overall operating duration, etc.), helping to identify energy wastage in the facility easily.

4. Support tools

Challenge: The major issue the traditional HVAC systems face is that the diagnostic is feasible only after BMS is fully commissioned and online. In these systems, the commissioning of a single valve is carried out at a time. Furthermore, time-consuming and inconvenient trial & error methods are used to determine the system errors. In traditional HVAC systems, the setup used to connect the system with different software tools is not standardized.

Advantages of using Danfoss digital toolbox during commissioning: Advanced HVAC systems feature multiple components which need to be selected, sized, installed and commissioned. Danfoss eases this complexity by providing an extensive toolbox that helps you select the right products in the required combinations; it supports the easy commissioning of 64 actuators in one go. Danfoss support tools aid in quick fault identification using alarms. There are many troubleshooting tools available for remote access and system analysis. The freely available desktop application that supports BACnet and Modbus bus-communication protocols can be used with the support tools.

Conclusion:

Certain studies carried out by the International Energy Agency (IEA) have shown that almost 30% of the global energy consumption is due to the lighting and the HVAC systems used in the buildings. Therefore, to enhance the energy efficiency of the commercial buildings and increase their occupants' comfort, smart technologies need to be installed in the buildings.

Danfoss digital hydronics is undoubtedly the most innovative solution which can be used to digitize and optimize the HVAC systems of your commercial buildings; hence in advanced terms, it is referred to as the HVAC 4.0. The Danfoss NovoCon digital actuators support the BMS by providing real-time data related to all the performance parameters. With the continuous data analysis and the remote adaptation of the HVAC systems to continuously enhance their performance, Danfoss ultimately helps in reducing the energy consumption at highest operational efficiency.