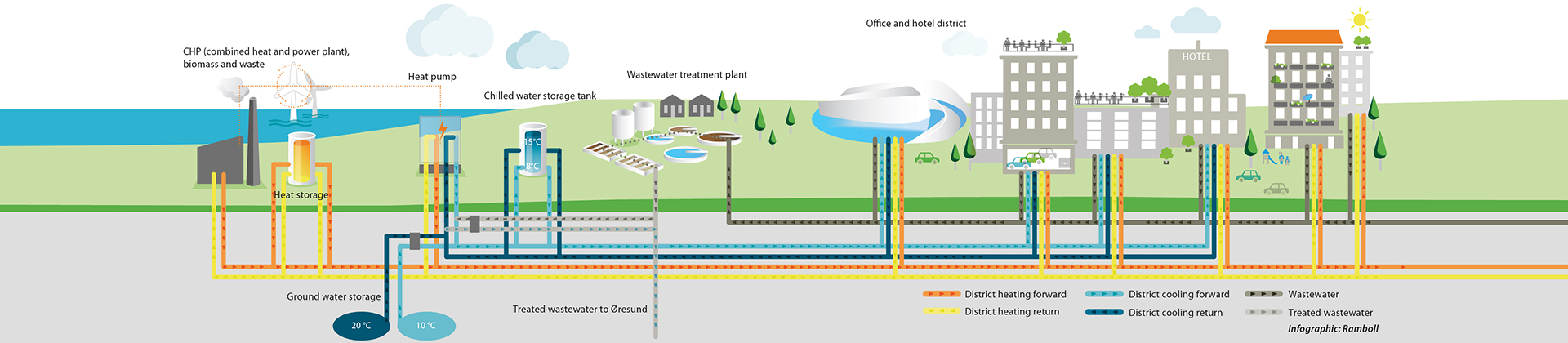

DENMARK: Building owners in Taarnby Municipality, Greater Copenhagen, enjoy competitively priced and environmentally friendly cooling thanks to a world-first project. This project integrates the production of district cooling and district heating in combination with ground source cooling and chilled water storage in one facility that also exploits surplus heat from a nearby wastewater treatment plant. The symbiosis allows the utility company not only to provide competitively-priced cooling for residents, but also to generate more cost-effective heating for the district heating network.

Sector coupling teamwork

Discover how great teamwork has driven clever solutions in this unique project. The key team members: Antoni Trumulis and Anders Dyrelund, Ramboll; Hasmik Margaryan and Raymond Skaarup, Taarnby.

Sector coupling makes best use of renewable energy

The project is a good example of sector coupling, providing a way to use green renewable electricity when prices are low and avoid electricity consumption during peak hours with high prices.

In the new Taarnby facility, surplus green electricity is channeled into a combined heating and cooling system that stores the energy in hot or cold water. Thanks to a chilled water storage tank, that can hold 2,000 cubic meters of cold water, Taarnby Utility is able to respond to the fluctuations of the electricity market and produce cooling when electricity prices are low. Moreover, the tank can provide peak capacity and stabilize the operation of the heat pumps.

Schematic overview of the Taarnby project

A smart consumer

In Denmark, where more than 45% of the electricity production is derived from renewable sources, low electricity prices are usually an indication of surplus supply from wind power. From the point of view of the power system, Taarnby Utility becomes a smart consumer. Offering a much-needed energy demand response, Taarnby can purchase power at the times when the power supplier needs to sell it, for example when the weather conditions are optimal for generating wind power and/or outside of peak hours on the grid. Likewise, production can be disrupted in case of shortage of capacity for power generation or distribution.

Synergy in partnership

The unique project, commissioned in 2020, was devised by Ramboll consulting engineering company and the main stakeholders are local building owners, Taarnby Public Utility and the heat transmission company CTR. Cooperation between these stakeholders and a mutual ambition to seek out an environmentally friendly and cost-effective solution has been key to the development and implementation of the Taarnby facility.

Danfoss AC drives control pumps and fans

Danfoss Drives has supplied 27 AC drives for phase 1 of the new facility – from small drives for building

ventilation to large drives up to 400 kW for controlling the capacity of the heat pumps. The main selection criteria were high energy efficiency and high reliability. Other Danfoss products are also applied at the plant: Danfoss SONDEX® heat exchangers transfer the thermal energy and Danfoss refrigeration controls are used in the heat pump system.

District heating and cooling case studies

-

if (isSmallPicture) {

DrivePro® Lifecycle Services secure maximum uptime for Rothes CoRDe

DrivePro® Lifecycle Services secure maximum uptime for Rothes CoRDeSCOTLAND: The Rothes CoRDe plant, a biomass-fired combined heat and power (CHP) plant, ensured maximum uptime thanks to several DrivePro® Lifecycle Services.

-

if (isSmallPicture) {

From waste to sustainable energy: electricity and heating for the city

From waste to sustainable energy: electricity and heating for the citySCOTLAND: In line with the zero-waste objectives of the Scottish government, treatment of non-recyclable urban waste contributes to eliminating landfill whilst generating electricity and heat. Equipped with high-efficiency VACON® NXP drives, the process generates heat enough to supply 25,000 households.

-

if (isSmallPicture) {

VLT® drives run the world’s smartest district energy system

VLT® drives run the world’s smartest district energy systemTaarnby Municipality within Greater Copenhagen is the first to integrate the production of district cooling and district heating in combination with ground source cooling and chilled water storage in one facility that also exploits surplus heat from a nearby wastewater treatment plant. This symbiosis allows the utility company to provide building owners in the district with competitive and environmentally friendly cooling – while generating more cost-effective heating to the district heating network.

-

if (isSmallPicture) {

Electrification and sector coupling achieve CO2 goals at FlexHeat Nordhavn

Electrification and sector coupling achieve CO2 goals at FlexHeat NordhavnDENMARK: The FlexHeat district heating plant at Copenhagen’s Nordhavn harbor emits 315 fewer tonnes per annum of CO2 than the LPG gas-based alternative.

-

if (isSmallPicture) {

Seawater cools Copenhagen city, cutting emissions by 70%

Seawater cools Copenhagen city, cutting emissions by 70%DENMARK: Two district cooling centrals in Copenhagen use seawater from Copenhagen Harbor for their cooling systems. For seven years, VLT® drives controlling pumps and compressors have proven their worth, ensuring high efficiency and impressive security of supply.

-

if (isSmallPicture) {

World leader in biogas reduces CO2 emissions by 50,000 t annually

World leader in biogas reduces CO2 emissions by 50,000 t annuallyBy generating power and heat from biogas instead of fossil fuels, MEC-BioGas reduces its CO2 footprint by 50000 tpa. Danfoss VLT® drives ensure optimal uptime in the 24/7 operations.