Exhaust gas is a telltale revealing hidden secrets about the health and efficiency of the engine. In fact, exhaust gas temperature is one of the more critical operating parameters of the vessel engine. Constantly monitoring temperature levels in the exhaust gas help ensure high efficiency, high uptime and precise control of emissions.

For many years, diesel engines have been the preferred technology for propulsion and power generation onboard vessels due to their fuel economy, ease of maintenance and robustness. However, to ensure longevity of the engine it is important to continuously monitor critical parameters such as pressure and temperature during operation.

Second to oil pressure, exhaust gas temperature (EGT) may be the most critical operating parameter on the diesel engine, and excessive EGT gives early warning to potentially serious engine problems.

Increased exhaust gas temperature can help diagnose the following conditions prior to severe engine damage:

- Cooling system problems

- Combustion problems (typically air/fuel mix)

- Fuel system problems

Increased EGT on all cylinders may indicate that the air system is fouled, typically the air filter, blower, cooler or scavenge air ports. It may also reveal contamination of the exhaust gas, e.g. the protection grid, nozzle ring, turbine wheel, SCR or exhaust gas boiler.

On the other hand, increased EGT on a single cylinder may indicate a defect fuel valve or low compression caused by either a leaking exhaust gas valve or worn out piston rings.

In this way, EGT is a very important indicator providing valuable information about different parts of the engine and potential problems. The rule is that the more precise and reliable the temperature measurements are, the higher uptime and fuel efficiency can be achieved.

Ships in international charter are typically in continuous operation for months at a time. This places great demands on the durability of all equipment onboard. The new temperature sensor MBT 5116 from Danfoss has been developed to meet the demands for reliability and durability and is equipped with two sensor elements to provide redundancy.

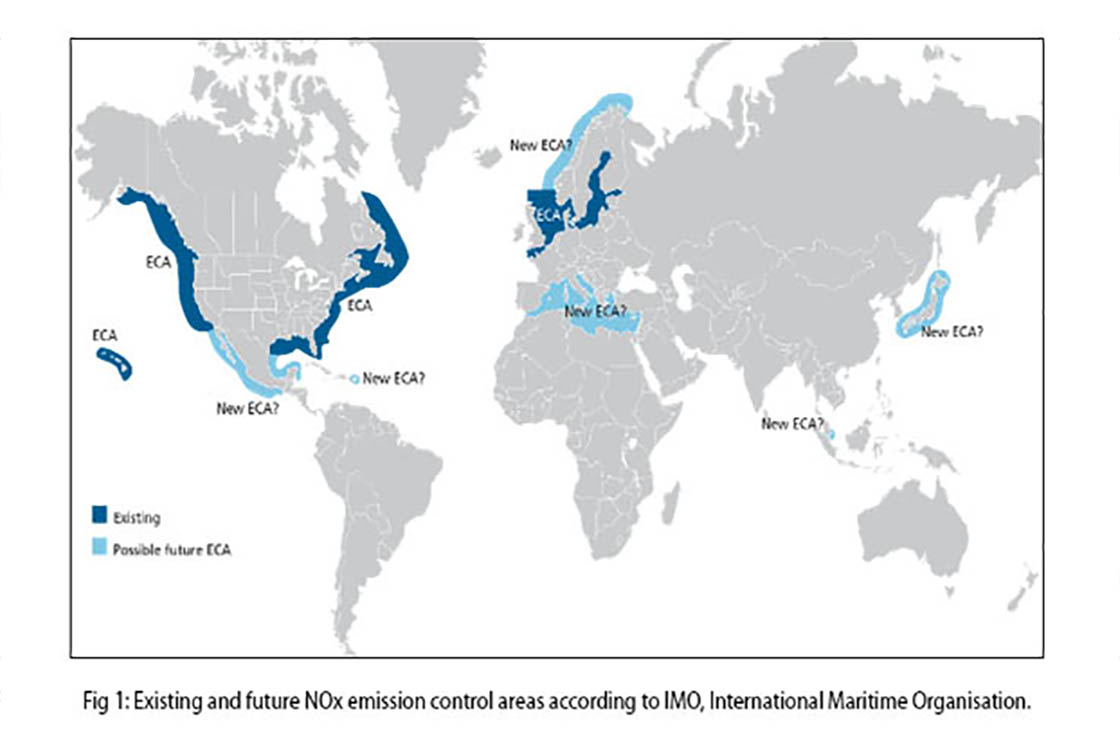

Precise Emission Control – Another Aspect of EGT Control. The MARPOL Annex VI convention continues to impose ever stricter limits for emissions of sulphur (SOx) and nitrous (NOx) oxides from marine operations. Violating the threshold values implies severe penalties in terms of fines but also in terms of image loss in a time when acidification of coastal areas attracts international attention.

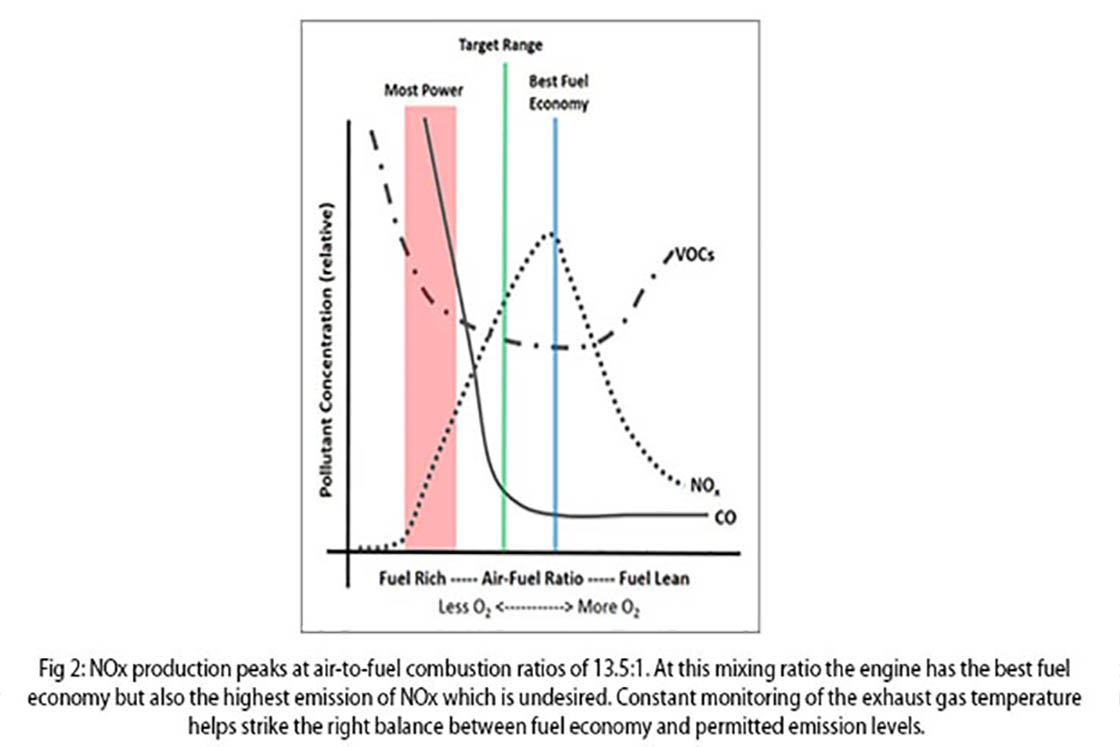

Exhaust gas temperature combined with measurements of the NOx and SOx content are important indicators of the quality of the combustion of the main engine and thereby help diagnose incomplete combustion and non-complying emissions.

Diesel emissions are categorized as carcinogenic and stringent emission legislation is enforced in emission controlled areas. This legislation makes it mandatory to monitor the exhaust gas temperature to meet regulations on NOx and SOx emissions, while still maintaining a competitive fuel economy.

|

|

Balancing emissions and fuel economy requires extremely precise temperature control. The new MTB 5116 from Danfoss is developed for the harsh environment of the exhaust gas system and with double-sensor elements. The sensor allows highly reliable operational control and at the same time a clean conscience that emissions are within the permitted levels in coastal areas and at sea.