For the commercial food service and related industries – which rely daily on large quantities of ice for food displays, safety, preparation, beverages and more – the ability to reliably and cost efficiently produce ice can have an impact on a business’ operation. Between 2005 and 2010, Manitowoc Ice, Inc., the Wisconsin-based manufacturer of commercial ice machines, became interested in taking their product portfolio one step further and turned to Danfoss with the idea to design an ice machine that would improve customers’ sustainability efforts by operating on natural refrigerants.

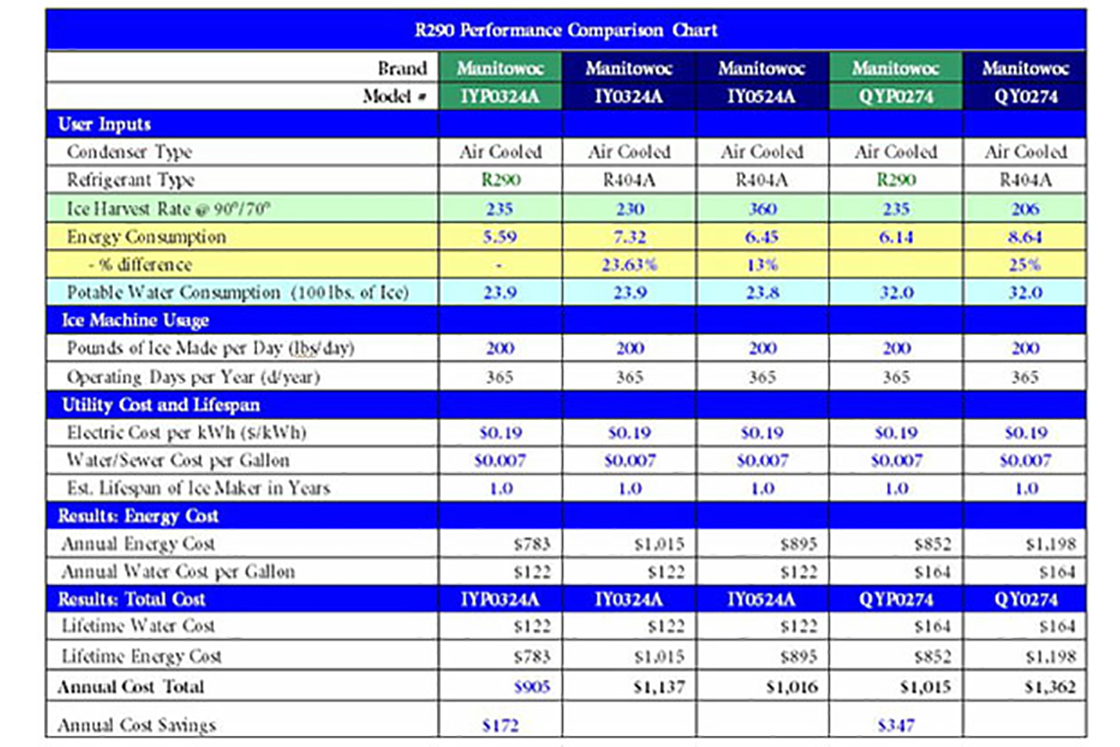

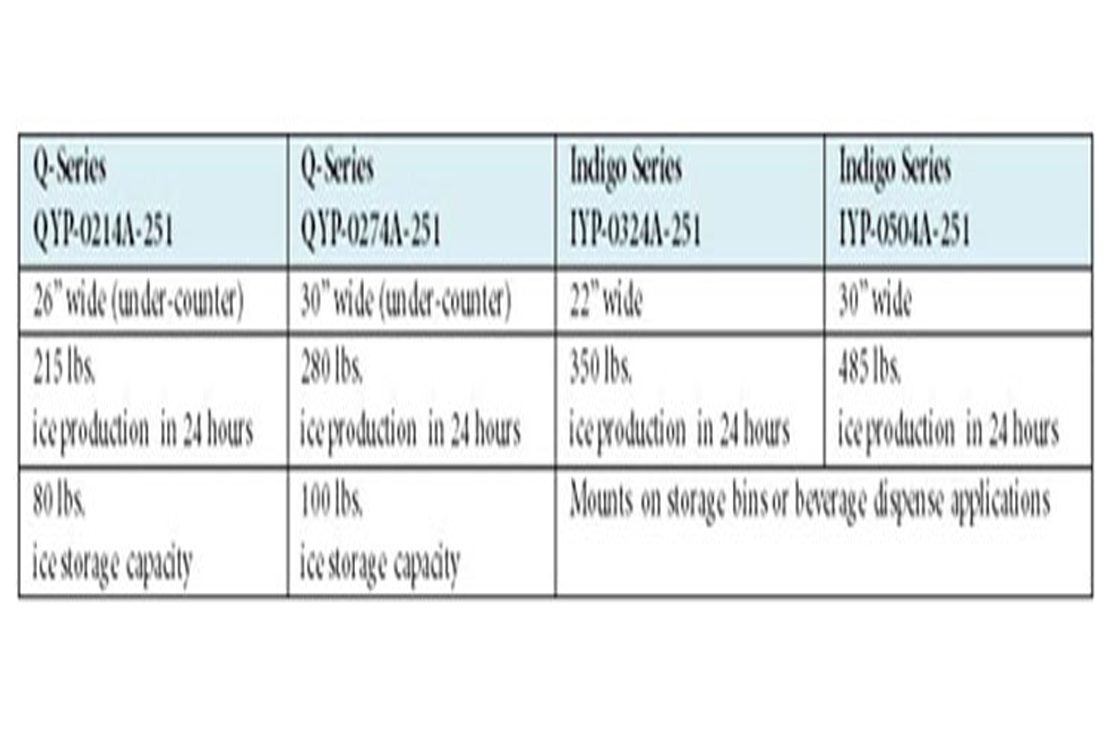

The collaboration with Danfoss led to the development of two new models within Manitowoc’s Indigo Series and two Q-Series under-counter units that are cooled by R290, or propane, which Manitowoc introduced in mid-2011. The use of an environmentally friendly hydrocarbon refrigerant enables Manitowoc to offer customers a product that has zero ozone depletion potential (ODP) and low global warming potential (GWP), which also improves energy efficiency and reduces operating costs.