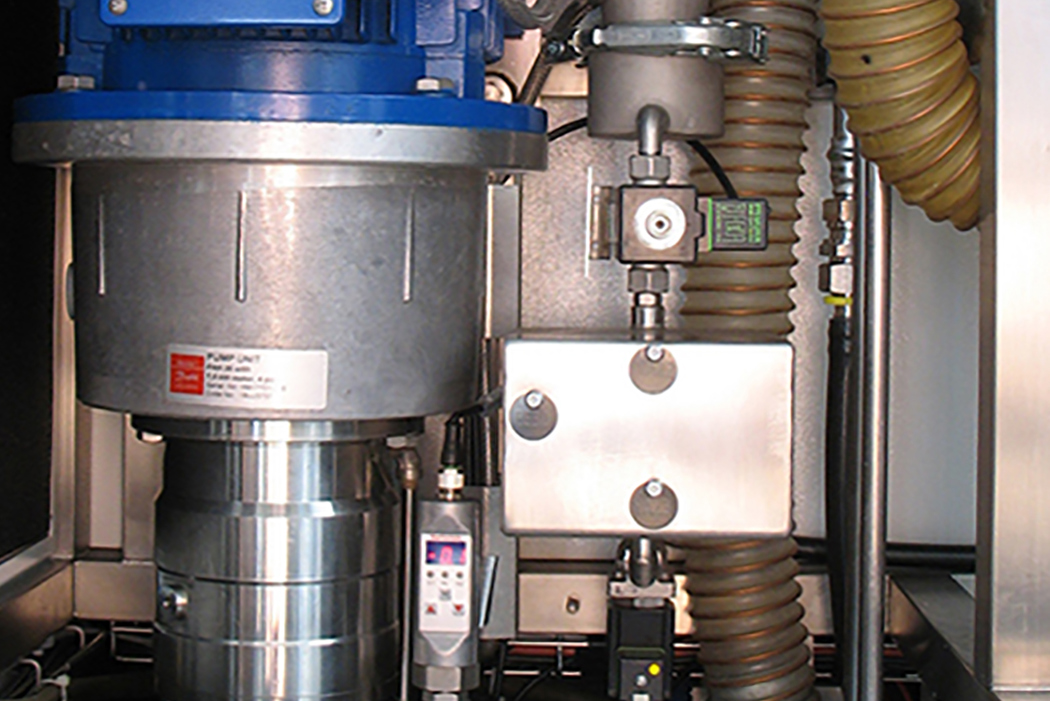

While the aggressive nature of DI is ideal for cleaning parts, it is also highly corrosive against the pumps that bring it to high pressure. Therefore only pumps whose wetted parts are made for stainless steel can be used.

According to Wolfgang Wiederer, head of sales & project engineering at SLE, the search for a suitable all-stainless steel pump soon led to the Danfoss PAHT. “We tried working with other stainless steel pumps, but their reliability was lower and their maintenance costs were higher.

Many of our inline parts cleaners are installed in production facilities that run three shifts a day, year-round, so dependability and long intervals between service are key parameters for us. Danfoss leads the way in pump reliability with at least 8,000 hours of operation before service as quite normal.”

Danfoss’ axial piston technology has other advantages for SLE. Since the pumped medium - even a highly aggressive one such as DI - supplies all the lubrication necessary; there is thus no risk of the pump’s oil lubricant contaminating the parts to be cleaned. Danfoss PAHT pumps are also considerably smaller than centrifugal pumps - making it easier for SLE to integrate them into their compact cabinets. And the constant pressure enabled by the axial piston principle suits SLE’s requirement for consistent cleaning pressure perfectly.

PAHT pumps

PAHT pumps