Milk cooling tanks ensuring accurate temperature control

Dairy farms rely on highly efficient cooling of the milk to keep the milk at a consistent temperature of about 4°C in the milk tanks until the milk is collected for further processing.

Milk is stored at the farms in either closed or open milk tanks. To maintain the quality of the milk it is quickly cooled from 38°C leaving the cow to 4°C in the milk tank. The milk tank is typically equipped with a mixer to accelerate the cooling process and homogenize the milk.

In the Danfoss range of solutions for efficient cooling of milk tanks you will find solutions suited for any tank size, any evaporation temperature and for all types of refrigerants, including low GWP refrigerants. The accurate temperature control of the Danfoss components also ensures that the milk does not freeze to avoid depleting of the fresh milk quality. Our solutions are tailored to comply with national/regional legislation.

Features and benefits

Air cooled condensing units especially suited for milk tanks, equipped with hermetic compressors, mainly reciprocating and scroll compressors, sometimes semi hermetic compressors

Customized condensing units sized to fit tank dimensions and ambient temperatures

A wide range of controls to secure reliable refrigeration

Long service life

Related products

-

if (isSmallPicture) {

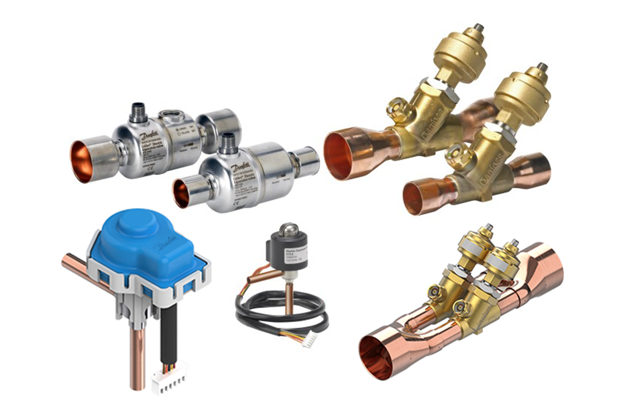

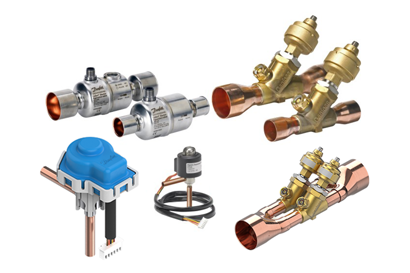

ETS electric expansion valves

ETS electric expansion valvesETS is a series of electric expansion valves for precise liquid injection in evaporators for air conditioning and refrigeration applications. The valve piston and linear positioning design is fully balanced, providing bi-flow feature as well as solenoid tight shut-off function in both flow directions. ETS valves are compatible with electronic control solutions from Danfoss and other manufacturers.

-

if (isSmallPicture) {

Water regulating valves

Water regulating valvesPressure operated water valves are used for regulating the flow of water in refrigeration plants with water-cooled condensers.

-

if (isSmallPicture) {

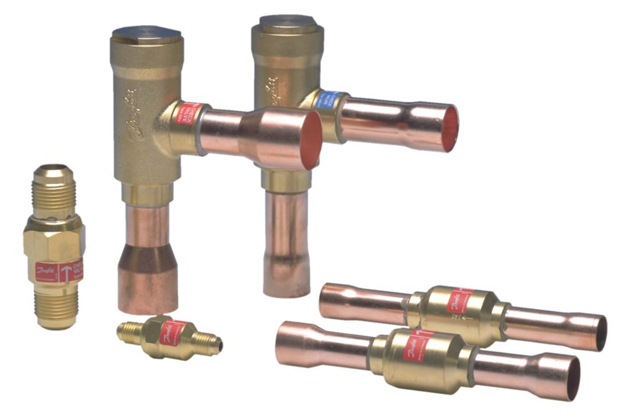

NRV refrigeration check valves

NRV refrigeration check valvesNRV and NRVH can be used in liquid, suction and hot gas lines in refrigeration and air conditioning plants with fluorinated refrigerants. NRV and NRVH can be supplied with flare and solder connections. They are also available with oversize solder connections providing flexibility in the use of check valves.

-

if (isSmallPicture) {

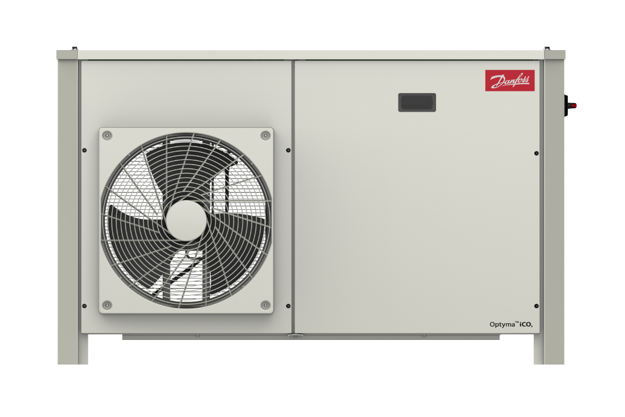

Optyma™ iCO₂

Optyma™ iCO₂Optyma™ iCO₂ 4.6 kW (MBP) condensing unit is a robust and low-noise solution for natural refrigerant R744 compatibility.

-

if (isSmallPicture) {

Condensing units

Condensing unitsOptymaTM ranges of condensing units match your commercial refrigeration application needs, with their unique versatility and simplicity to install. Multi-refrigerants, using low-GWP and natural refrigerants, highly efficient, they are a perfect fit for small to mid-size cold rooms, display cabinets, milk cooling tanks, fermentation rooms and much more.

Learning

Do you want to learn more about milk cooling tanks?

Contact us

For further information, please contact us.