A Hyperloop Pod is an extraordinarily powerful yet lightweight vehicle. On 22 July 2018, in Elon Musk's high-speed SpaceX competition in Los Angeles, the Danfoss-Drives-sponsored Dutch Delft Hyperloop student team will attempt to break the current land transportation speed record of 384 km/h set by Virgin Hyperloop One.

Danfoss Drives sponsors the team

Atlas01 is the second Hyperloop Pod to be created and it has been built by the Danfoss Drives-sponsored Dutch Delft Hyperloop student team. Pictured here, from left to right, are Giannis Papazoglou, Vlad Petrescu, Willemijn Peters, Rico Hageman, Pieter-Bas Bentinck and Kevin van der Toorn. Koen Verschoor, son of Danfoss Drives Country Manager Dirk Verschoor, is also on the team.

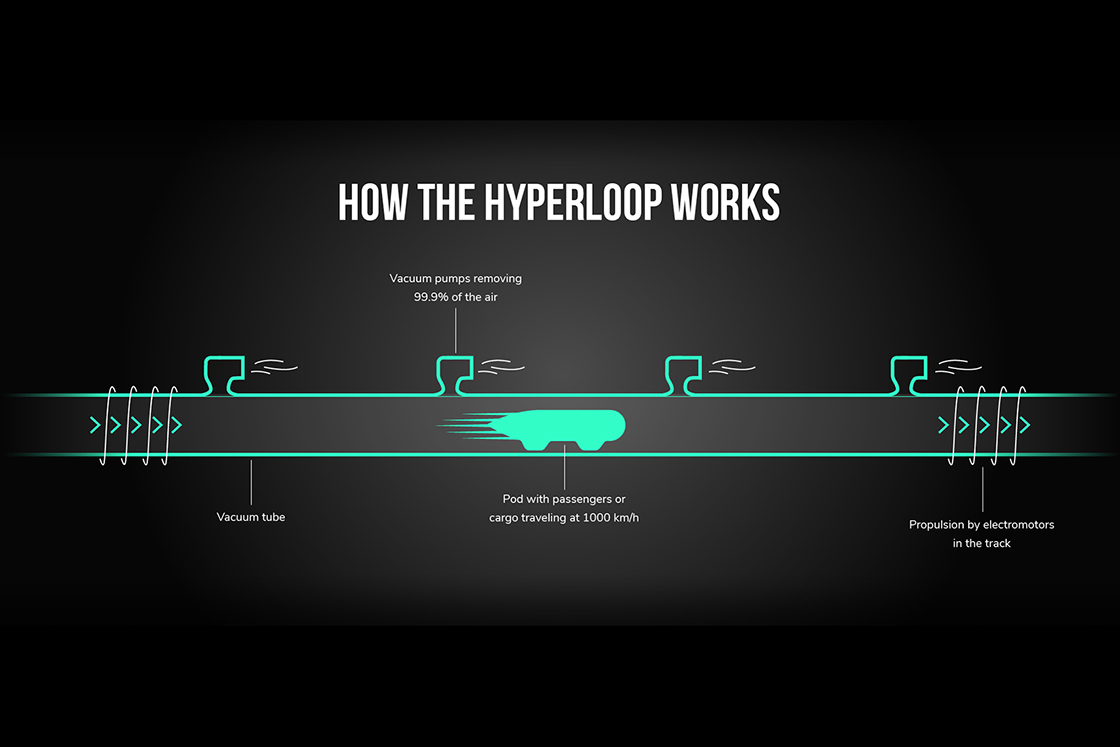

After the victory of the first Delft Hyperloop team in January 2017, the second team is keen to equal this performance and to break the speed record. The ultimate goal is to make a Pod that reaches 1000 km/h.

From Amsterdam to Paris in 30 minutes!

The Pod is modular and consists of two parts: the launch module and the passenger module. Both modules are being built, but only the launch module will be placed in the SpaceX near-vacuum tube to try to break the world record. The modular design is very promising as it offers a simple possibility to switch from economy class module to business class or cargo module.

To test the Atlas01, the students had to find a location with a powerful electrical power supply. This brought them to the Danfoss Drives Application Development Center (ADC) in Gorinchem, Netherlands.

Since September 2017, 37 students, including 27 full-time, have been working on the Hyperloop Atlas01. Over the past eight weeks, a number of these students have frequently been found at the Danfoss Drives ADC in Gorinchem. A container is placed in the parking lot, surrounded by sandbags, with access to the DC power supply of 650 Vdc/200 kW.

Pieter-Bas Bentinck, Chief DriveTrain, and Bachelor of Aerospace Engineering, describes the design process: "During the design of the first Hyperloop Pod in January 2017, no drive system was allowed. For this edition, we will have a full-scale concept in the tube. When hovering on magnets, there is more friction. The option with an electric motor and a wheel proved to be the fastest. The wheel must have as much energy as a 200 kg Pod. The power is extracted from lithium polymer batteries. We first tested the motor with a wheel, then we started testing the brakes. In total there are 10 wheels and a drive wheel."

Willemijn Peters, Chief Suspension & Testing, and 3rd year student of Applied Physics, explains: "The track has a length of 1200 meters. Within those 1200 meters, we have to achieve the highest possible speed. But, of course, the Pod has to come to a standstill before the end of the track. The deceleration is five times higher than the acceleration. We have approximately 200–300 meters braking distance. Special attention is given to the suspension of the entire vehicle and the damping of the vibration. We are very happy that we’ve had the opportunity to test here at the Danfoss Drives ADC."

Watch this exciting video of the Pod being revealed, and keep up to date with the team’s progress on their Facebook page and on their vlog.

Good luck to the whole team in Los Angeles. We hope the state-of-the-art facilities at Danfoss ADC help them to break the record.