Energy efficiency and the potential of variable speed control

Climate action is needed, and with the Paris agreement, countries around the world are aiming to reduce their carbon footprint. To secure the 1.5 °C target, broad action including a shift to produce energy based on clean and renewable sources is necessary. But the cleanest energy is the energy that we do not use. We win most of all when we apply the “Efficiency First” principle, by pursuing every opportunity to reduce energy consumption.

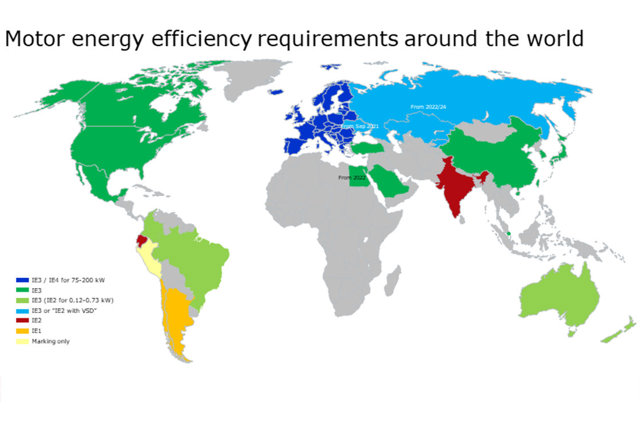

Efficiency regulation

Based on defined efficiency classes, legal requirements defined throughout the world ensure the use of energy-efficient products. Motors, drives, and drive-motor systems are classified according to their energy efficiency. In Europe, this legal framework is called Ecodesign.

When designing an optimum drive-motor system, efficiency is naturally an important factor. However, to achieve the most effective and economical system, the user must consider more than the efficiency classes: The interaction of all components as a system solution determines the efficiency of the application.

On this page we’ll explain how easy it is to understand the relevant efficiency classes and how to use them.

Energy saving potential with variable speed control

Electric motors used to drive fans, pumps, compressors and other applications account for more than 50% of the global electricity consumption. That’s why increasing the energy efficiency of motors will significantly reduce global energy consumption. And the potential is even greater when applying an AC drive, also known as a variable speed drive (VSD), to control the motor. Most fans, pumps and compressors do not need to run at full speed and torque all the time. A drive controls motor speed and torque to constantly adapt to the actual need. Reducing motor speed reduces energy consumption considerably. In this way, applying a drive increases the energy efficiency – typically by up to 20-30%. At the same time, the fan or pump will be exposed to less wear and tear and therefore enjoy a longer lifetime. Therefore, there is a large untapped potential in using more VSDs.

International Directive for Energy Efficiency

The energy classes for drives and for systems are defined in the international standard IEC 61800-9. In Europe it is referenced as EN 61800. These standards define how to calculate energy classes IE1 and IE2 for drives and IES1 and IES2 for systems. Driven by the Ecodesign Directive, the requirements for energy efficiency in drive technology continue to increase.

New minimum efficiency requirements apply in July 2021.

Component versus system approach

Improving the energy efficiency of components in a motor-driven system like a pump will increase the overall system energy efficiency. For both motors and AC drives, defined energy classes indicate the level of efficiency at component level. However, the potential for optimizing energy efficiency is significantly greater at system level, where a drive controls the motor, and where each component is selected with system optimization in mind. The cost of system optimization is also considerably lower, and the payback time for a drive is often very short. To find the best combination of motor and VSD, consider the Energy Efficiency Indicator (EEI) for the combined drive-motor system.

Read more about the system philosophy of efficiency optimization