Filter driers are key components in any commercial or residential refrigeration application. The market for filter drier technology, however, is complex with a lot of different solutions available and great variation when it comes to quality and pricing.

Choosing the right filter drier is essential to providing reliable, long lasting protection of any refrigeration system.

Selecting a filter drier for a particular application requires careful evaluation of several technical factors such as type of system, connections, size of the system, moisture adsorption capacity, filtration capability, design pressures, and others. This article takes a closer look at two of the more widespread filter drier technologies – with steel housing and loose desiccant with spun copper tube, to shed more light on the pros and cons of the different solutions.

The basic need: keep the refrigeration system dry and clean

The filter drier, whether solid core or loose desiccant, has to perform two basic functions to ensure a high-performing refrigeration system and minimize system breakdowns. First of all, the filter drier has to adsorb any moisture in the system that can lead to system freeze-ups or creation of harmful acids. By keeping the moisture level in the system low, the risk of freeze-ups, corrosion and acid formation is minimized. Secondly, the filter drier provides filtration to keep the system clean by removing foreign substances that may potentially harm close tolerance parts of the refrigeration system like the compressor, solenoid valves, expansion valves and capillary tubes.

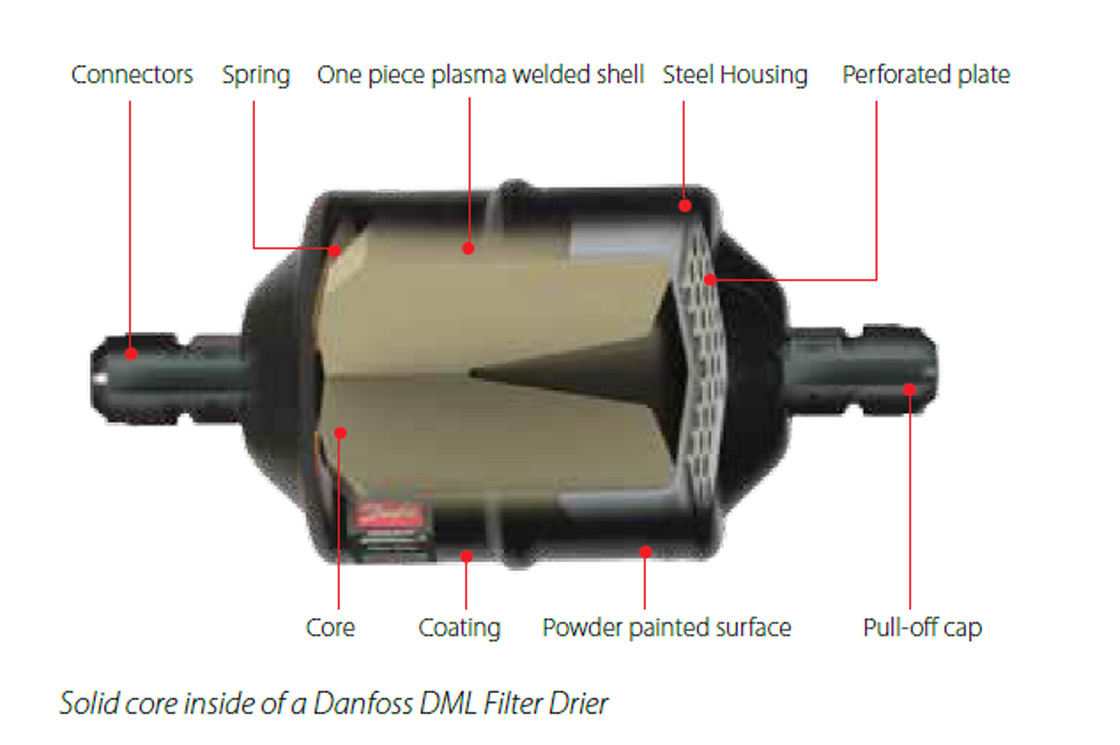

The spun copper technology performs the tasks of drying and filtration by means of loose beads enclosed in a thin copper casing tube and with a built-in wire mesh or fiberglass mat for solid particulate filtration. The solid core technology performs moisture adsorption and filtration as an integrated process when the refrigerant passes through molecular sieve material and a polyester felt mat.

Varying manufacturing processes

The two filter drier types are manufactured using fundamentally different processes. While both processes are highly automated, the first step in each process is the formation of the structure into which either the solid core or loose desiccant material is ultimately placed.

The steel housing is comprised of stamped sheet metal and, depending on the size of the filter drier, is either hermetically sealed via a plasma welding process after the solid core and other components are inserted, or, designed to enable easy replacement of the solid core.

On the other hand, the spun copper structure is typically manufactured from copper tubing placed in a high speed lathe. Depending on the capacity required, various tooling is used to work one end of the copper tube to refrigeration industry standard sizes, the loose desiccant material is added, and the opposite end of the tubing is then prepared by the lathe to match.

It is important to add that some spun copper devices contain a solid core desiccant.

Differences in moisture and filtration capacity

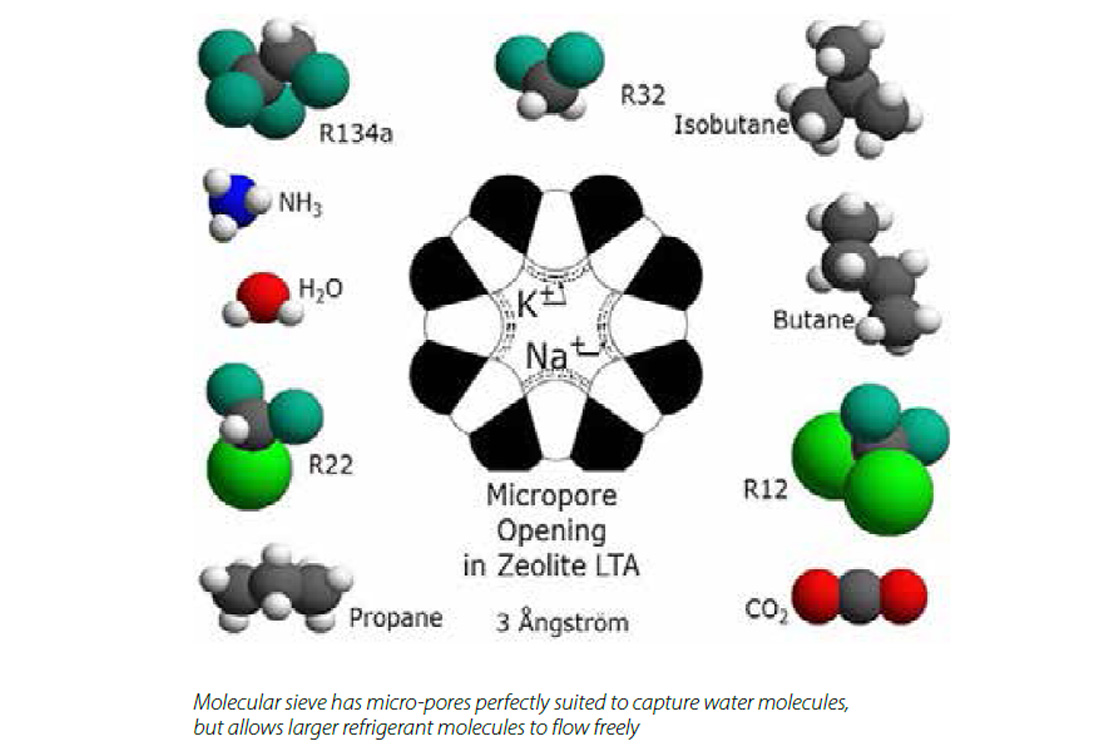

The molecular sieve of the solid core filter drier retains the highest amount of water due to the strong bond between the molecular sieve and the water. Core beads contain Zeolite crystals. It has the ability to selectively sort molecules based primarily on a size exclusion and polarity process. This is due to a very regular pore structure of molecular dimensions. The micro-pore opening is large enough for water molecules to enter but not refrigerant molecules. Spun copper technology uses small beads coated with a binder necessary to prevent the beads from disintegrating during daily operation. The beads, however, produce slower and less efficient adsorption mainly due to the binder coating.

Upon delivery, the initial moisture content of the solid core and the spun copper technology has been found to be significantly different. Experiments1 have shown that the solid core filter drier can be delivered with a moisture level up to three times lower than the spun copper. In some cases the moisture content of the spun copper has been as high as 10% when delivered, as compared to only about 2% for the solid core filter drier. In other words, the moisture adsorption capacity of the solid core filter drier typically exceeds that of spun copper, and, when specified for the same application extends the lifetime and reduces the maintenance costs of the system.

When comparing the filtration capacity of the two technologies you will also find sizeable differences. Contrasted with slim, spun copper technology, the relatively large diameter of the solid core filter driers minimizes pressure drop and enables more effective particle filtration. The most commonly used spun copper variants offer a dirt retention size of 15 micron. The solid core filter driers offer dirt retention down to particles of 25 microns with minimal pressure drop. Tests have shown that particles below 25 micron don’t compromise the system's performance, but they can instead clog the drier and reduce the efficiency of the system by creating larger pressure drops.

The typical design of the spun copper means that the diameter of the perforated filtration sheet at the inlet of the spun copper is smaller than the body of the filter drier, which may lead to problems with clogging and subsequent pressure drop reducing the flow and thereby the efficiency of the refrigeration system.

Molecular sieve has micro-pores perfectly suited to capture water molecules, but allows larger refrigerant molecules to flow freely

Variations in MWP levels

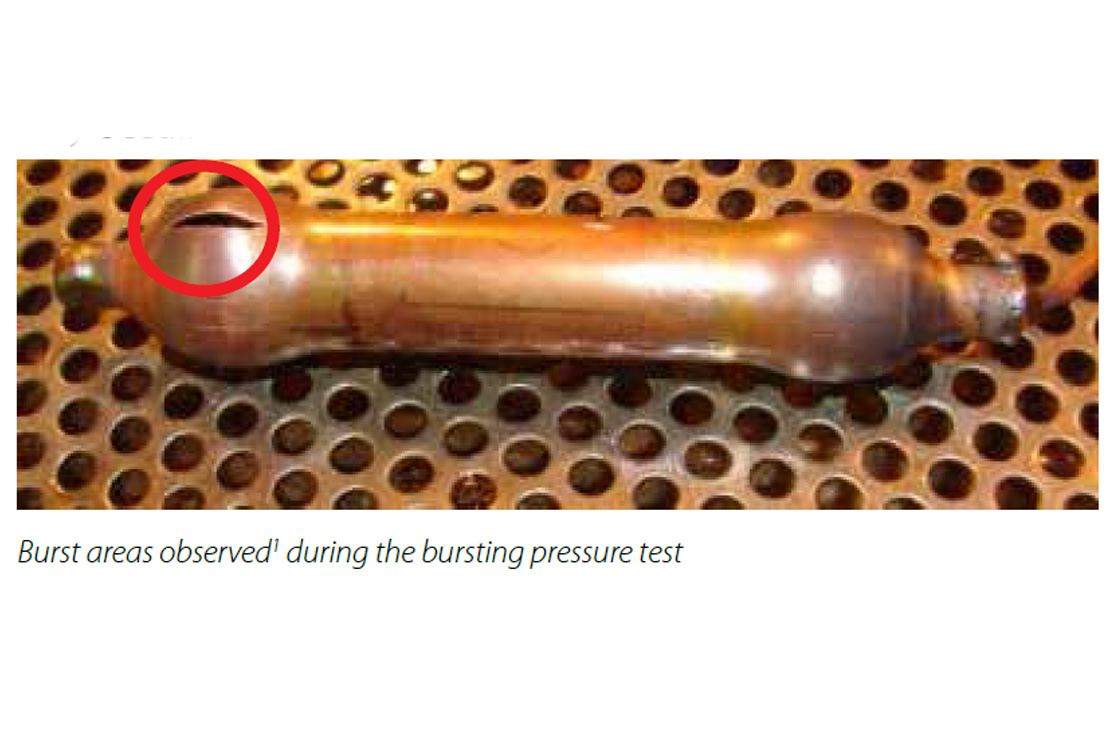

Filter driers are designed for different Maximum Working Pressure (MWP) levels. Due to the extremely thin copper casing of the spun copper solutions, the MWP limit is normally around 24 bar (348 psi), whereas solid core solutions allow MWP up to 46 bar (667 psi). Some applications such as Glass Door Merchandisers using refrigerants like R410A and Bottle Coolers using HC refrigerants may require even higher pressure for efficient operation, and new solid core filter driers are now in the market with MWP levels up to 46 bar (667 psig).

The bursting pressure of most solid core technologies have been tested according to the UL 207 standard requiring the burst pressure to be rated as five times the design working pressure of the system. The tests have proven that the filter driers can withstand pressures up to 300 bar (4,351 psi). The increased robustness of the filter driers increases the safety of the system during daily operation and minimizes the risk of refrigerant loss in case of system failure. The ability of the solid core technology to withstand high pressures for a longer period of time also allows operators more time for detection of abnormalities in the system and for shutting down the system before more serious failures may occur.

Total cost of ownership

The price and quality range of spun copper filter driers is wide, but generally the spun copper solutions tend to be less expensive and lower quality compared to solid core technology. Seen over the entire life cycle, however, the solid core technology has the potential to outperform the spun copper due to its superior quality and performance during daily operation and its high durability and long service life require less need for maintenance and replacement.

This means that the solid core filter drier seems to be the most attractive choice for those who need more capacity and better performance or for smaller applications where uninterrupted operation and less service calls are first priorities.