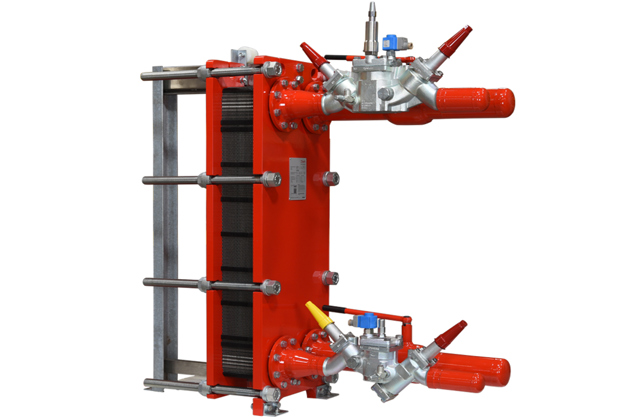

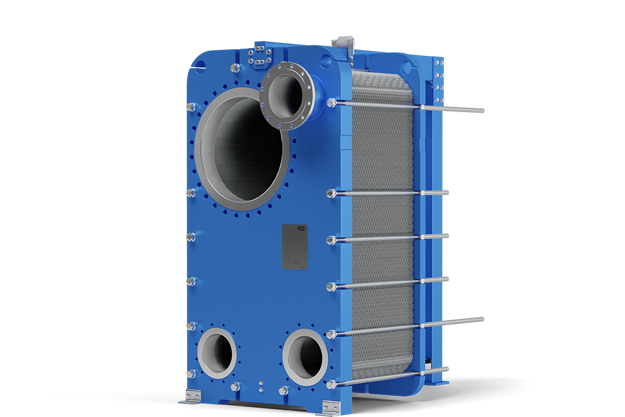

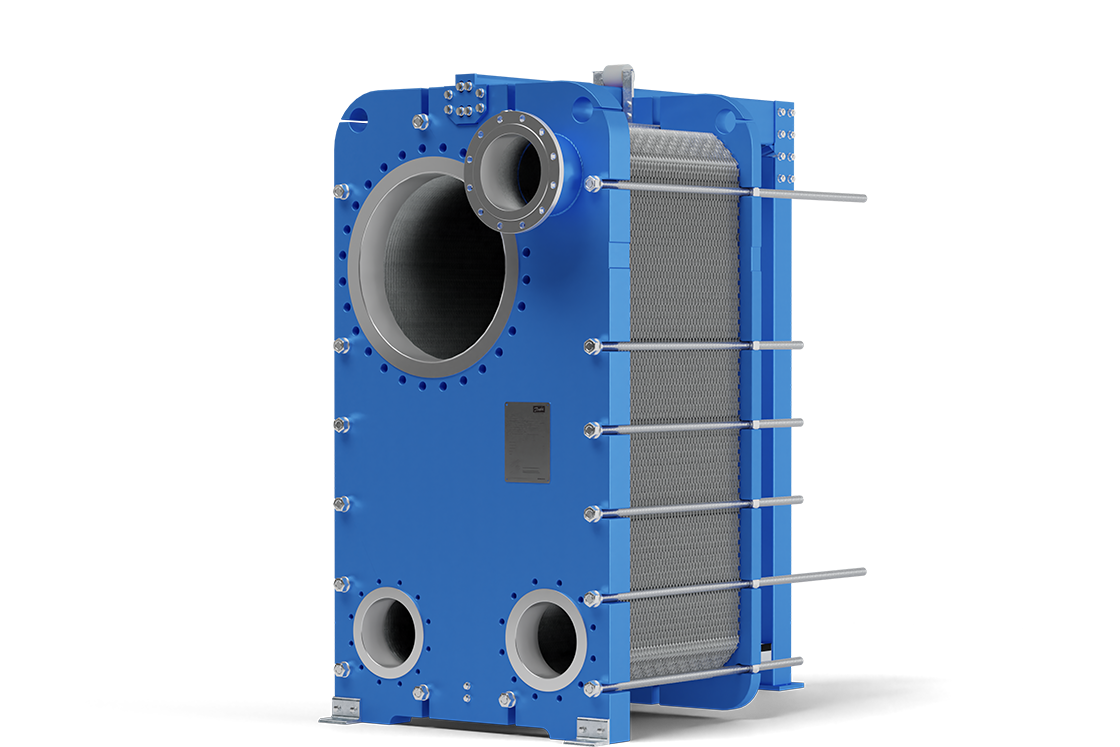

Our SONDEX® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. Innovative technologies and smart design make our standard plate heat exchangers a stellar investment and the go-to choice for standard duties. With higher heat transfer efficiency and optimisation, these heat exchangers offer the most efficient thermal performance.

We have one of the largest plate portfolios in the world and we customise each heat exchanger to meet your exact requirements. The versatile design and high thermal efficiency make them the perfect solution for a wide range of applications, including the transfer of heat across a diverse temperature difference.

Features and benefits

Experience the benefit of an individually customised solution that perfectly matches your requirements and lowers your energy consumption, thus improving energy efficiency. Our heat transfer solutions ensure that there are no stagnant zones and create high flow turbulence for optimal results.

High performance for a low pressure drop eliminates unnecessary burdens on your system and optimises overall system performance.

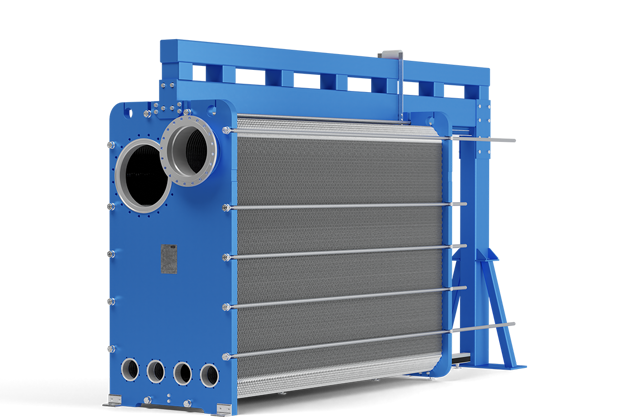

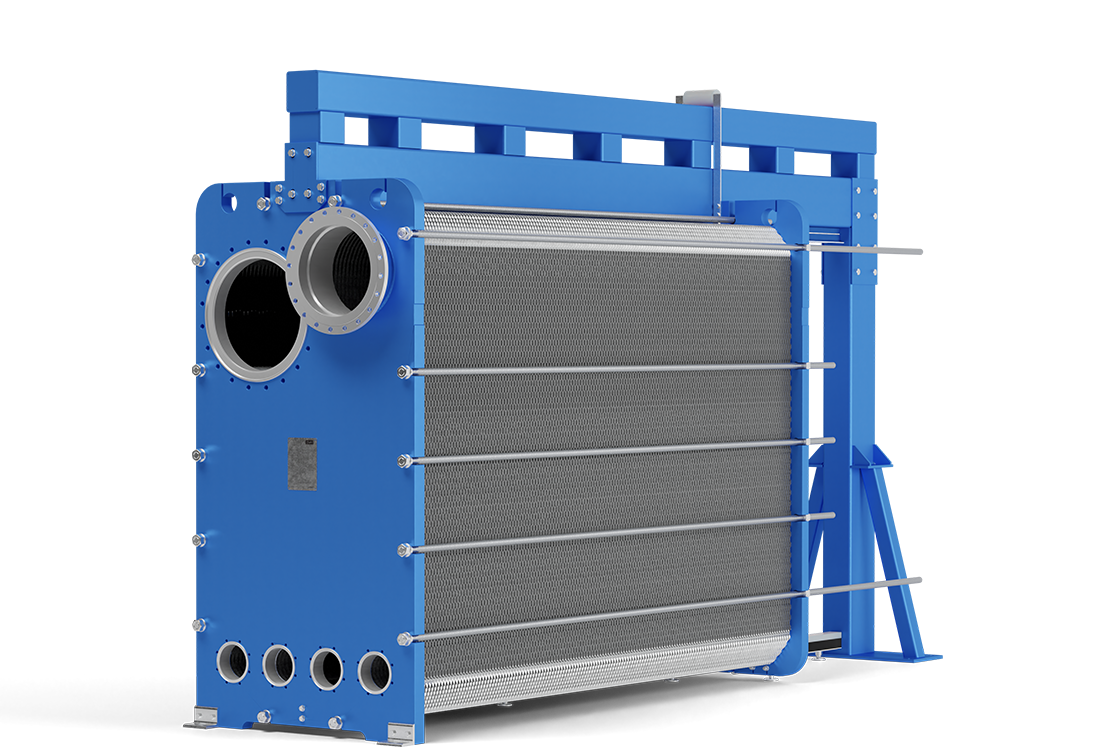

We design single-pass solutions when possible, as they are the preferred choice for almost all duties. With all connections on the head you do not need to disconnect the heat exchanger from the piping to perform inspection, cleaning, or service.

Gasketed plate heat exchangers are uniquely designed with specific plate features, including frame and pressure plates. These special features ensure the entire heat transfer surface is utilised, thereby enhancing the heat exchanger performance. thus improving energy efficiency. Our heat transfer solutions ensure that there are no stagnant zones and create high flow turbulence for optimal results. The design results in a compact solution with a small footprint, simple installation, and easy access for maintenance.

Discover how the SONDEX® gasketed plate heat exchanger operates.

From design and construction to working principles, we take you through the key features behind these high-efficiency heat transfer solutions.

Applications

-

HVAC industry - e.g. district cooling solutions using seawater and groundwater as cooling source - e.g. district heating solutions using, for example, solar and geothermal energy as heating source

-

Marine/offshore industry - e.g. central and lubrication oil cooling

-

Dairy/food/beverage industry - e.g. pasteurisation, heat recoveries, and duties that require gentle treatment

-

Sugar industry

-

Biogas industry

-

Pulp and paper industry

-

Heavy industry

-

Mining industry

-

Petrochemical industry

-

Chemical industry - e.g. waste heat recovery from condenser water

Technical specifications

-

Connections from DN25 to DN600 (1" to 24")

-

Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards

-

Plate materials: AISI 304/316, titanium, SMO, Hastelloy*

-

Gasket materials: EPDM-HT, NBR-HT, Viton*

-

Plate lengths up to 5.5 m (18 ft)

-

Flow rates up to 7,200 m3/h (31,700 gpm)

-

Working pressure up to 35 bar (500 psi)

-

Working temperatures from -20 °C to 180 °C (-4 °F to 356 °F)

*Other materials are available upon request.

D-plate technology

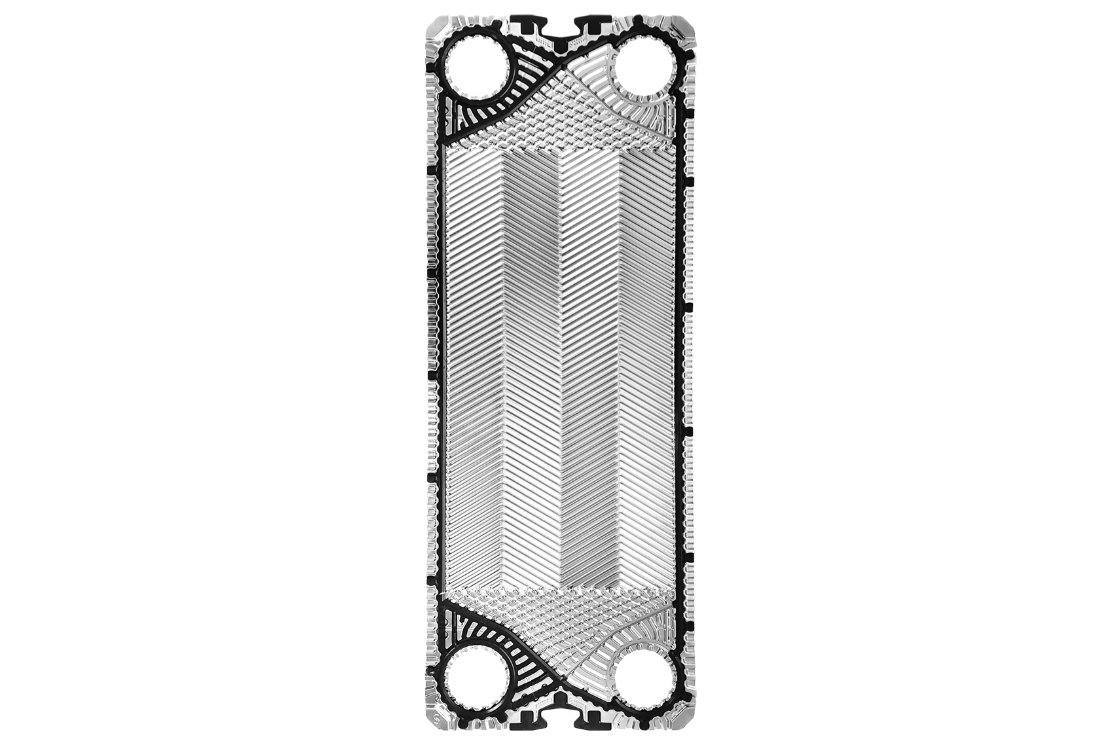

Our Danfoss engineers have enhanced the way heat exchanger plates are designed with the introduction of the new D-plate series. With various pressing depths and corrugated plates, the media flow in an opposite direction in alternate channels between the plates. This results in transferring heat effectively. Drawing on years of experience within heat transfer technology and deep application knowledge, we have made significant upgrades to the traditional Fishbone plates to truly redefine the way we think of heat exchanger plates.

SONDEX® Fishbone plates

SONDEX® Fishbone plate pattern technology is used for the vast majority of our plate heat exchangers. The pattern is designed for high thermal performance while using the allowed pressure drop in the most efficient manner. Available with different pressing depths, pattern pitch and angles – each plate has a pattern that is optimised for a certain duty. These heat sensitive plates provide optimal performance and guarantee efficient heat transfer area across a full range of applications.

Our product range includes small to large heat exchangers suitable for all types of industries. For instance, heat transfer solutions like our SONDEX® condensers and evaporators are designed for advanced duties. They accommodate high flow rates and work under diverse system pressures and temperatures.

At Danfoss, we believe that every heating or cooling challenge can be met with innovative heat exchanger solutions. Whether it's hot water production in domestic hot water systems or handling aggressive, corrosive fluids in the chemical industry, we have a solution in our vast product range.

Delving Deeper into our Heat Transfer Solutions

At Danfoss, we ensure that every product in our range delivers maximum efficiency and optimal performance. Our plate heat exchangers and gasketed plate heat exchangers are robust, reliable, and built to last, reflecting our commitment to quality and customer satisfaction.

Our heat exchangers, known for transferring heat efficiently across the entire heat transfer surface, are designed with the specific plate features that optimize heat transfer area. This results in a smaller footprint and increased energy efficiency, making our solutions a top choice across various industries.

Explore our product range and discover how we can enhance your system's performance, reduce energy consumption, and ensure the efficient transfer of heat. Get in touch with us today for more information on how our plate heat exchangers can make a difference in your operations.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A world of heat exchangers | English | Multiple | 18 Nov, 2024 | 7.2 MB | |

| Brochure | A world of heat exchangers | Bulgarian | Bulgaria | 04 Oct, 2024 | 5.3 MB | |

| Brochure | A world of heat exchangers | Romanian, Moldavian, Moldovan | Romania | 10 Oct, 2024 | 9.7 MB | |

| Brochure | D-plate technology - Experience D-power | English | Multiple | 30 Jan, 2023 | 6.0 MB | |

| Brochure | Danfoss Design Code (DDC) | English | Multiple | 06 Sept, 2021 | 497.0 KB | |

| Brochure | Danfoss Design Code (DDC) | French | France | 29 Nov, 2021 | 302.6 KB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Chinese (CN) | Multiple | 17 Jan, 2024 | 9.6 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 17 Jan, 2024 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 01 Sept, 2023 | 9.6 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 01 Aug, 2024 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 20 Sept, 2022 | 9.7 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 22 Dec, 2023 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Chinese (CN) | Multiple | 05 Jun, 2025 | 9.6 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 13 Sept, 2023 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 13 Sept, 2023 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 15 Sept, 2023 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 13 Sept, 2023 | 9.6 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 01 Sept, 2023 | 13.0 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Russian | Multiple | 17 May, 2024 | 16.5 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 02 Jun, 2025 | 9.6 MB | |

| Brochure | Gasketed plate heat exchangers - Next-generation heat transfer solutions | English | Multiple | 22 Nov, 2024 | 4.4 MB | |

| Data sheet | Gasketed Plate Heat Exchangers DN 100 | Lithuanian | Multiple | 27 Jan, 2021 | 3.0 MB | |

| Brochure | Heat exchangers for the power industry | English | Multiple | 19 Nov, 2024 | 4.8 MB | |

| Brochure | SONDEX® Free Flow sugar brochure | English | Multiple | 27 Nov, 2024 | 7.2 MB | |

| Brochure | SONDEX® Traditional Plate Heat Exchangers | English | Multiple | 12 Feb, 2024 | 9.4 MB |

Related products

-

if (isSmallPicture) {

Semi-welded plate heat exchanger for industrial refrigeration ammonia applications

Semi-welded plate heat exchanger for industrial refrigeration ammonia applicationsThe semi-welded plate heat exchangers are optimized for industrial applications. The semi-welded plate heat exchangers from Danfoss is designed for ammonia systems and can be used for applications such as Condensers, flooded and pumped evaporators, Sub-coolers, Desuperheaters, Superheaters, Economizers and Oil coolers.

-

if (isSmallPicture) {

Condensers

CondensersOur SONDEX® condensers are the perfect choice for special applications that regular plate heat exchangers cannot handle. Designed to accommodate high-volume vapor flows, this product features a large inlet for the vapor stream. Combined with a short residence time, the optimal condensation conditions are created – even for low-pressure vapor duties.

-

if (isSmallPicture) {

Evaporators

EvaporatorsSONDEX® evaporators are designed to handle advanced evaporation duties. Using semi-welded plate cassettes, the media are guaranteed to never mix. The plate cassettes are designed to ensure the optimal level of turbulence on both sides, while providing an even distribution of the media for superior performance and product quality.