Danfoss Dynamic Valve™: a simple solution to a daily challenge

Danfoss Dynamic Valve™ is an innovative radiator valve with a 2-in-1 valve design. It combines a thermostatic radiator valve and a differential pressure controller for accurate temperature control and automatic hydronic balancing in a single product.

The built-in differential pressure controller eliminates pressure fluctuations in a two-pipe heating system. By using Dynamic Valve™ a perfectly controlled and automatic hydronic balanced heating system is simply established.

For designers

Dynamic Valve™ is good news for everybody involved in designing or specifying a two-pipe heating systems. It has all the advantages of automatic hydronic balancing combined with optimal temperature control.

For installers

By installing the valves you also install automatic balancing at the same time. To commission the system correctly the valves just have to be set to correct maximum flow at each radiator.

For building owners

Dynamic Valve™ is a product typical to use in residential buildings. Many owners, occupants and other users will recognise typical heating problems like noise, uneven heating and high energy bills. The indoor comfort will be greatly increased when Dynamic Valve™ is used.

Features and benefits

-

A 2-in-1 valve design for temperature control and automatic balancing

-

Built-in differential pressure controller

-

Maximum differential pressure 60 kPa

-

Limitation of maximum flow between 10 – 135 liters per hour

-

Available in DN 10/15/20

-

Available in Straight, Angle, Angle UK, Angle left and Angle right models

The new ISO 16484-4 standard finally sets a clear definition for dynamic balancing, and our dynamic valves are leading the change.

Our new article "New industry standard, ISO 16484-4, provides precise definition of dynamic balancing" talks all about it.

Read it here

See how the Danfoss Dynamic Valve™ works

Presentation on what is special about this thermostatic radiator valve, how it works and what the benefits are.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | Dynamic valve - Building owner brochure | Italian | Italy | 06 Mar, 2021 | 3.7 MB | |

| Brochure | Dynamic valve - Building owner brochure | Danish | Denmark | 29 Oct, 2014 | 375.3 KB | |

| Brochure | Dynamic valve - Building owner brochure | English | Multiple | 25 Jul, 2019 | 4.6 MB | |

| Brochure | Dynamic valve - Building owner brochure | Dutch, Flemish | Belgium | 14 Oct, 2014 | 365.2 KB | |

| Brochure | Dynamic valve - Building owner brochure | Hungarian | Hungary | 31 Aug, 2014 | 384.4 KB | |

| Brochure | Dynamic Valve - Designer and installer brochure | Polish | Poland | 16 Oct, 2019 | 755.1 KB | |

| Brochure | Dynamic Valve - Designer and installer brochure | French | Belgium | 17 Sept, 2017 | 1.6 MB | |

| Brochure | Dynamic Valve - Designer and installer brochure | English | Multiple | 25 Jul, 2019 | 11.2 MB | |

| Brochure | Dynamic Valve - Designer and installer brochure | German | Multiple | 06 Mar, 2023 | 1.4 MB | |

| Brochure | Dynamic Valve - Designer and installer brochure | Finnish | Finland | 29 Nov, 2023 | 2.5 MB | |

| Brochure | Dynamic Valve - Designer and installer brochure | French | France | 18 Nov, 2014 | 680.4 KB | |

| Brochure | Dynamic Valve — брошура для монтажників і проектувальників | Ukrainian | Ukraine | 15 May, 2018 | 639.4 KB | |

| Data sheet | Dynamic Valve Type RA-DV, Pressure Independent Radiator Valve | German | Austria | 29 Jan, 2026 | 4.0 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Estonian | Multiple | 04 Feb, 2026 | 2.7 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Italian | Multiple | 04 Feb, 2026 | 2.7 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Latvian | Multiple | 04 Feb, 2026 | 2.8 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Dutch, Flemish | Multiple | 04 Feb, 2026 | 2.7 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Spanish, Castilian | Multiple | 04 Feb, 2026 | 2.7 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Finnish | Multiple | 04 Feb, 2026 | 3.8 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Croatian | Multiple | 04 Feb, 2026 | 2.8 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Slovenian | Multiple | 04 Feb, 2026 | 2.8 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Serbian | Multiple | 04 Feb, 2026 | 2.8 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Ukrainian | Ukraine | 04 Feb, 2026 | 783.0 KB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | French | Switzerland | 03 Aug, 2021 | 1.4 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Romanian, Moldavian, Moldovan | Multiple | 04 Feb, 2026 | 2.9 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Czech | Multiple | 02 Dec, 2025 | 2.1 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Lithuanian | Multiple | 04 Feb, 2026 | 2.7 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | French | Belgium | 30 Jan, 2026 | 1.8 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | German | Switzerland | 29 Jan, 2026 | 2.9 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Danish | Multiple | 14 Jan, 2026 | 2.1 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Hungarian | Multiple | 04 Feb, 2026 | 2.8 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | Polish | Multiple | 29 Jan, 2026 | 2.8 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | French | Multiple | 30 Jan, 2026 | 1.8 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | German | Multiple | 14 Jan, 2026 | 1.9 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | English | Multiple | 14 Jan, 2026 | 2.1 MB | |

| Data sheet | Dynamic Valve™ Type RA-DV, Pressure Independent Radiator Valve | English | United Kingdom | 01 Dec, 2025 | 1.8 MB | |

| White paper | Practical guidelines for creating energy efficient multi-family residential heating systems | English | Multiple | 15 Oct, 2015 | 4.3 MB |

Related products

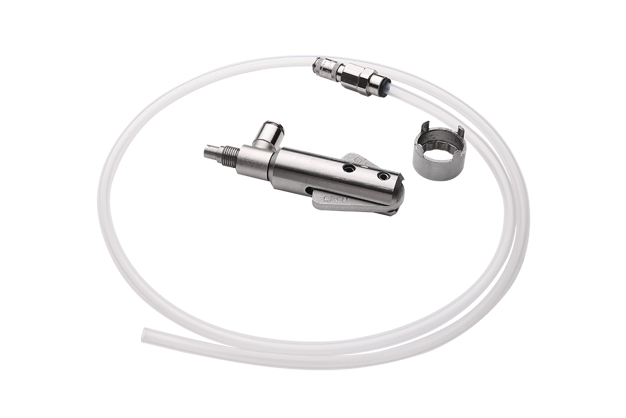

Optimize your heating system's performance with the Danfoss dP tool™ for PFM 100

The tool is used in heating systems to ensure that the valves are operating within the correct differential pressure range, specifically designed for Danfoss radiator valves.

Compatible with multiple valve models, including RA-N, RA-DV, RA-U, Danfoss BIV, and RA-IN, this tool ensures optimal flow regulation, energy efficiency, and system balancing. By preventing noise in valves, it extends their lifespan and enhances energy efficiency.

With its ease of use, the dP tool™ facilitates quick connection and measurement, streamlining service work for improved heating performance.

FAQ

Can Dynamic Valve™ be used for one-pipe heating systems?

No, Dynamic Valve™ can only be used in two-pipe heating systems

What is the maximum differential pressure Dynamic Valve™ should work under?

The maximum differential pressure is 0,6 bar or 60 kPa

Which sensors can be mounted on a Dynamic Valve™ ?

All sensors with a RA-connection (RAW, RAE, RAX, RAS-C, RAS-C2, RA 2000, living by Danfoss) can be used. However the Dynamic Valve™ should only be mounted in the inlet, so FJVR sensors should not be mounted.

Do you need to mount Dynamic Valve™ on all radiators in a heating system in order to achieve a proper system balance?

No, if there is a few radiators where Dynamic Valve™ can be mounted (e.g. due to a radiator with build-in valve) you can still achieve proper system balance. However it needs to be a little throughout a system.

Can flow be verified after Dynamic Valve™ is mounted?

Yes, this can be done by using the Danfoss dP tool™. With it you can measure whether the differential pressure of 0,1 bar or 10 kPa is achieved. The actual flow can be derived by looking up the actual pre-set value in the data sheet or on the Danfoss Pre-setting tool.

How does the Dynamic Valve™ work in a heating system?

The valve works in a way that the pre-set flow will be kept regardless of pressure changes in the heating system.

Can it create noise if someone closes their radiators in an apartment?

No, as the valve will keep a constant pressure over the valve cone, noise will not be an issue as long as the maximum differential pressure in the system is below 0,6 bar or 60 kPa

Can the Dynamic Valve™ be used with all heating sources?

Dynamic Valve™ can be used with all common used heating sources:

- Direct district heating (a pressure differential controller needs to be mounted);

- Indirect district heating;

- Gas boilers;

- Oil boilers;

- Heat pumps.