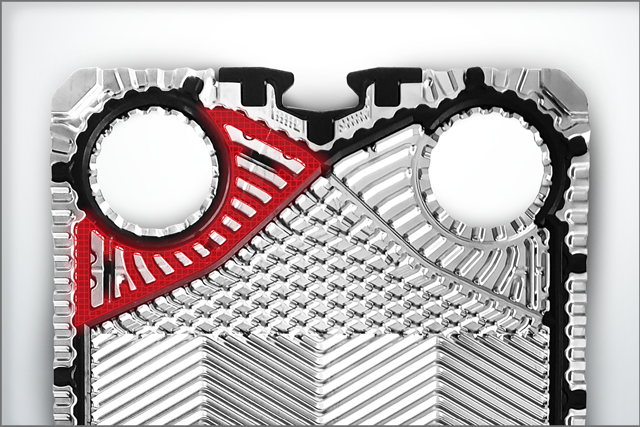

New plate design by Danfoss

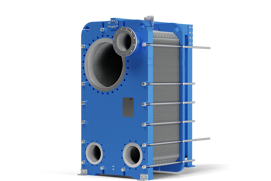

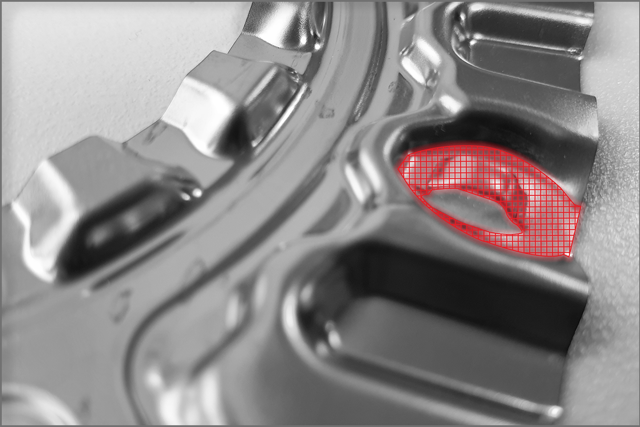

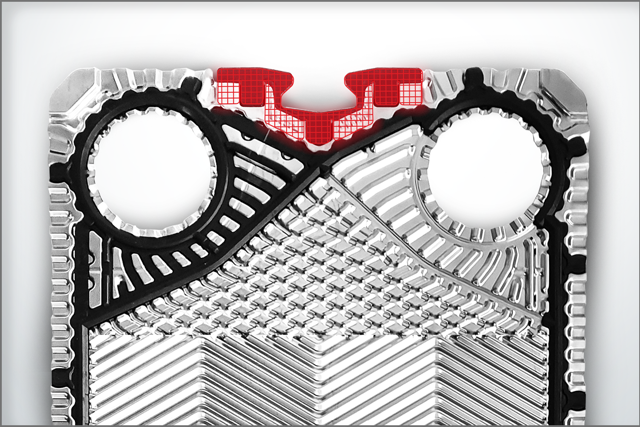

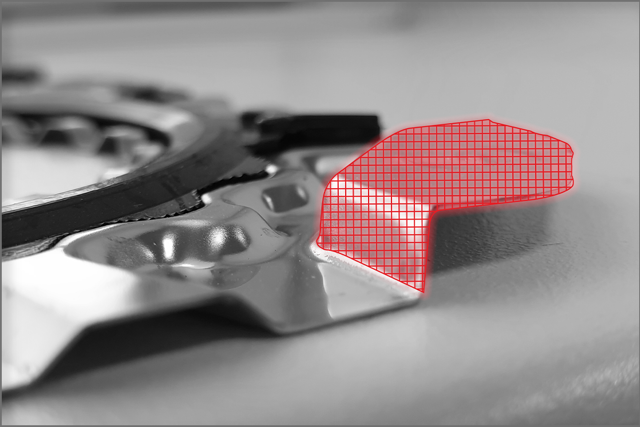

Our Danfoss engineers have enhanced the way heat exchanger plates are designed with the introduction of the new D-plate series. Drawing on years of experience within heat transfer technology and deep application knowledge, we have made significant upgrades to the traditional Fishbone plates to truly redefine the way we think of heat exchanger plates.

Maximising both performance and product lifetime, the D-plate series is a milestone in innovation and moves plate heat exchanger technology into a bright new era of advanced, yet simple solutions.

Experience D-power

Someone once said that all gasketed plate heat exchangers are not the same and that you should always look at the features on offer. This is a belief that we share at Danfoss, and why we never settle for mediocre solutions. Just because something works doesn’t mean that it can’t be improved, which is why we never stop innovating: to bring you the best solution possible.

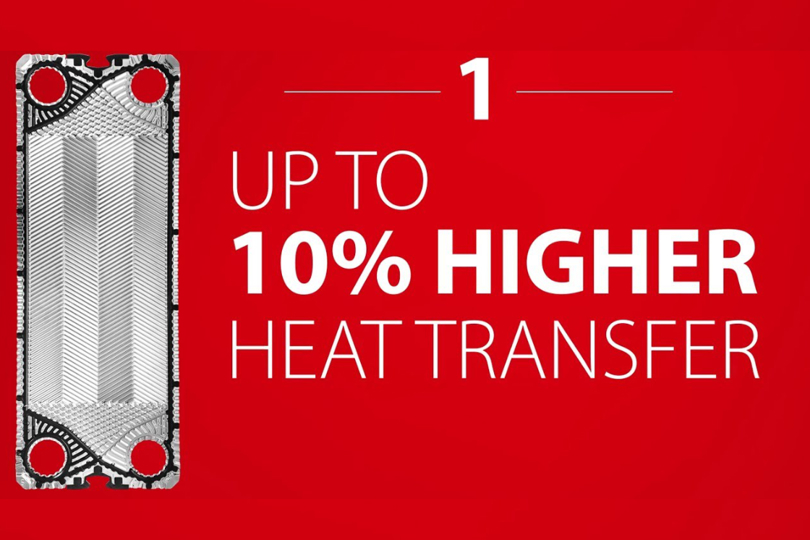

Powerful performance

We have increased the thermal performance of our plates by up to 10% compared to the usual plate design.

Experience D-power with the revolutionary new D-plate technology

Related products

-

if (isSmallPicture) {

Micro channel heat exchangers

Micro channel heat exchangersSave time and money with MCHE standard products. The introduction of micro channel heat exchanger condensers, which combine resource and energy efficiency with minimal use of refrigerants, is enabling the development of leaner, greener solutions. Select one of our standard products and you can buy any quantity of condensers, any time, large or small, directly from stock.

-

if (isSmallPicture) {

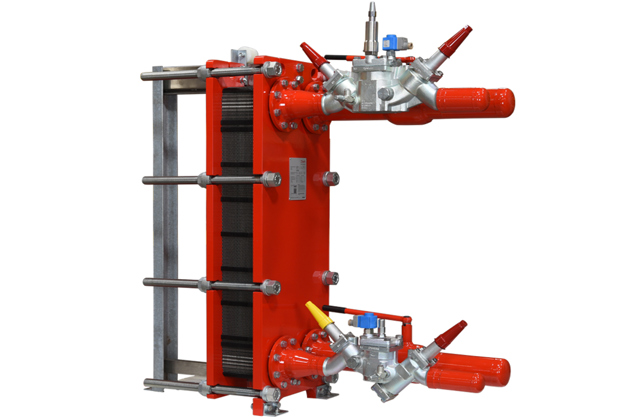

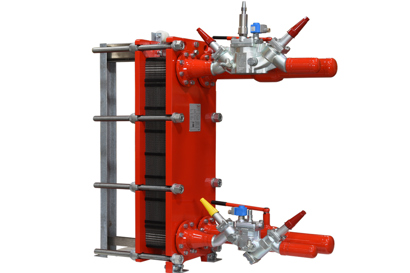

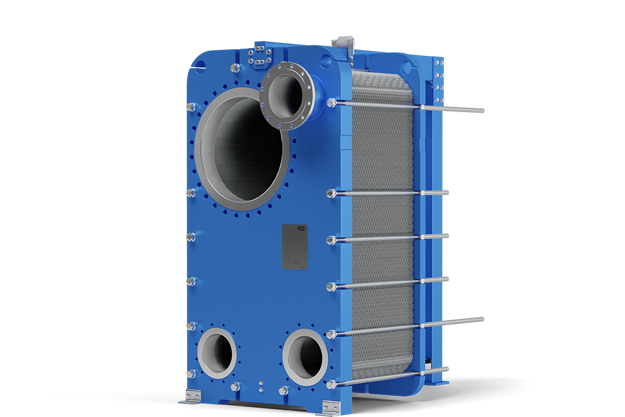

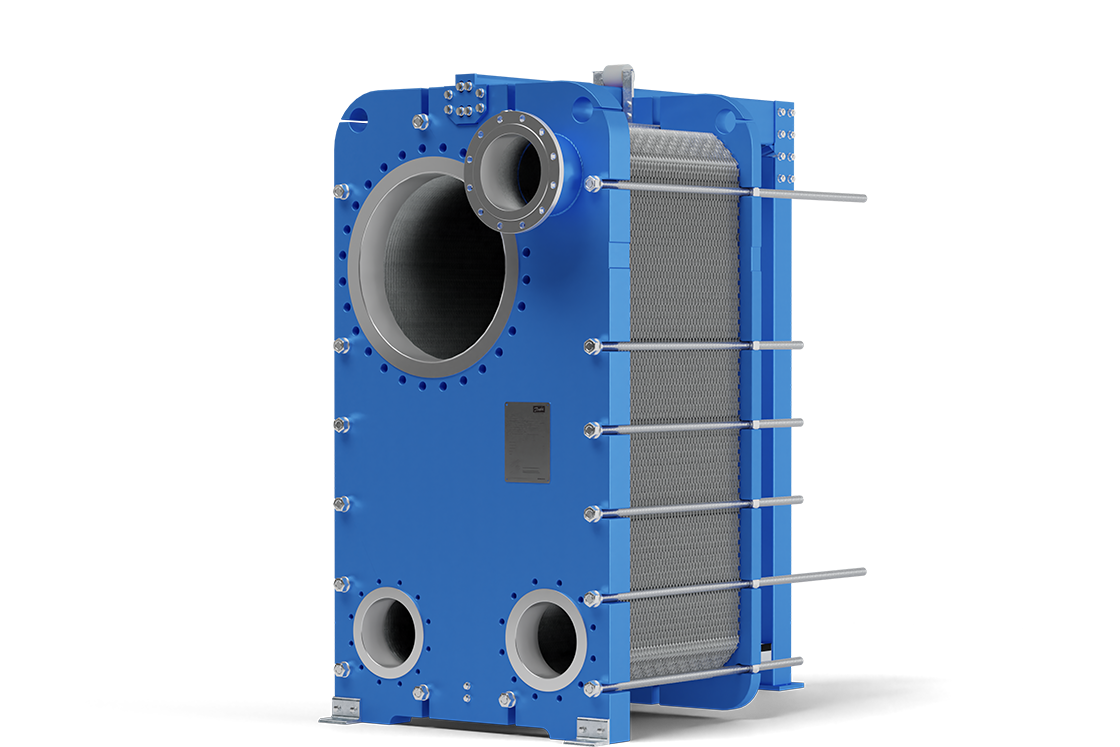

Semi-welded plate heat exchanger for industrial refrigeration ammonia applications

Semi-welded plate heat exchanger for industrial refrigeration ammonia applicationsThe semi-welded plate heat exchangers are optimized for industrial applications. The semi-welded plate heat exchangers from Danfoss is designed for ammonia systems and can be used for applications such as Condensers, flooded and pumped evaporators, Sub-coolers, Desuperheaters, Superheaters, Economizers and Oil coolers.

-

if (isSmallPicture) {

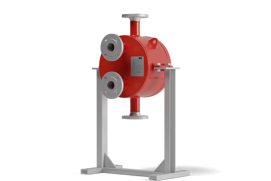

SONDEX® Plate and shell heat exchangers (SPS)

SONDEX® Plate and shell heat exchangers (SPS)Our SONDEX® Plate and shell heat exchangers (SPS) are perfect choices for condensation and steam heating duties. A fully welded plate pack makes the heat exchangers well-suited for handling aggressive media as well as high pressure levels and temperatures. Less space demanding and much lighter in weight, they are good replacements for shell and tube heat exchangers.

-

if (isSmallPicture) {

Condensers

CondensersOur SONDEX® condensers are the perfect choice for special applications that regular plate heat exchangers cannot handle. Designed to accommodate high-volume vapor flows, this product features a large inlet for the vapor stream. Combined with a short residence time, the optimal condensation conditions are created – even for low-pressure vapor duties.

-

if (isSmallPicture) {

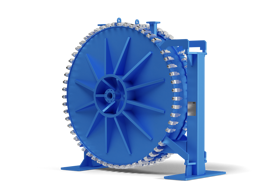

Spiral heat exchangers

Spiral heat exchangersExceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibers and solids, our SONDEX® Spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids. The design allows for a countercurrent flow that makes it possible to achieve very close temperature approaches.