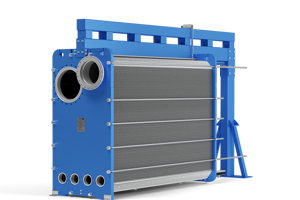

Our SONDEX® Free Flow plate heat exchangers are excellent choices for applications that use media with particle-rich contents, fouling tendency, or high viscosity. We customise each Free Flow heat exchanger to suit your application and media type. The contact-free plate channels ensure an unimpeded flow and long intervals between cleaning.

We set the new standard for improved performance and reliability when your media require gentle treatment and are unsuitable for regular heat exchangers due to viscosity, fouling tendency, or particle contents.

Features and benefits

-

Gentle treatment and even distribution of the media provide the highest possible product output quality.

-

High heat transfer efficiency and extended intervals between cleaning ensure operation for an entire campaign with minimum downtime and maximum value for money.

-

Large plate gap designed to counteract fouling with sizeable plate channels and no stagnant zones.

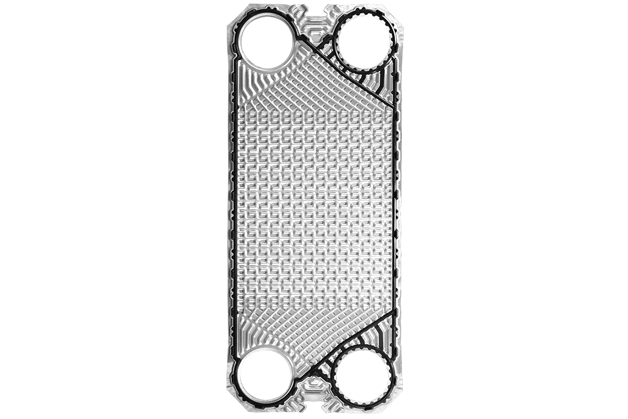

SONDEX® Free Flow plates feature deep and wide channels that provide enough room for media that contain fibers and particles, or high-viscosity media. The channels allow for efficient heat transfer and an ideal flow.

Applications

- Dairy/food/beverage industry

- e.g. food production, like juice and alcohol processing - Sugar industry

- e.g. sugar production, such as concentration of sugar content in sugarcane juice - Biogas industry

- Wastewater industry

- Pulp and paper industry

- Mining industry

Technical specifications

- Connections from DN25 to DN500 (1” to 20”)

- Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards

- Plate materials: AISI 304/316, titanium, SMO, Hastelloy*

- Gasket materials: EPDM-HT, NBR-HT, Viton*

- Plate heights up to 3.5 m (11.5 ft)

- Flow rates up to 1,600 m3/h (7,045 gpm)

- Plate gap from 5 to 12 mm (0.2” to 0.5”)

- Working pressure up to 10 bar (145 psi)

- Working temperatures from -20 °C to 180 °C (-4 °F to 356 °F)

*other materials available upon request

SONDEX® Free flow patterns

The SONDEX® Free Flow pattern is designed to treat media that is unsuitable for regular heat exchangers due to high viscosity, fiber and particle contents, or considerable risk of fouling.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A world of heat exchangers | Romanian, Moldavian, Moldovan | Romania | 10 Oct, 2024 | 9.7 MB | |

| Brochure | A world of heat exchangers | Bulgarian | Bulgaria | 04 Oct, 2024 | 5.3 MB | |

| Brochure | A world of heat exchangers | English | Multiple | 15 Sept, 2025 | 4.7 MB | |

| Operating guide | DA - Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | DE - Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | EN - Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 02 Jun, 2025 | 9.6 MB | |

| Operating guide | FR - Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 17 Jan, 2024 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 01 Aug, 2024 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 15 Sept, 2023 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 13 Sept, 2023 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Chinese | Multiple | 17 Jan, 2024 | 9.6 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 22 Dec, 2023 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 20 Sept, 2022 | 9.7 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 13 Sept, 2023 | 9.6 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 01 Sept, 2023 | 13.0 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 13 Sept, 2023 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 01 Sept, 2023 | 9.6 MB | |

| Brochure | Gasketed plate heat exchangers - Next-generation heat transfer solutions | English | Multiple | 15 Sept, 2025 | 5.6 MB | |

| Operating guide | HU - Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | IT - Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | PL - Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | RU - Gasketed and semi-welded Plate type heat exchangers | Russian | Multiple | 17 May, 2024 | 16.5 MB | |

| Brochure | SONDEX® Free Flow sugar brochure | English | Multiple | 27 Nov, 2024 | 7.2 MB | |

| Brochure | SONDEX® Traditional Plate Heat Exchangers | English | Multiple | 12 Feb, 2024 | 9.4 MB | |

| Operating guide | SV - Gasketed and semi-welded Plate type heat exchangers | Swedish | Multiple | 17 Nov, 2025 | 9.6 MB | |

| Operating guide | ZH - Gasketed and semi-welded Plate type heat exchangers | Chinese | Multiple | 05 Jun, 2025 | 9.6 MB | |

| Brochure | Брошура_Вдосконалені рішення теплообміну | Ukrainian | Ukraine | 01 Oct, 2025 | 3.8 MB |

Related products

The semi-welded plate heat exchangers are optimized for industrial applications. The semi-welded plate heat exchangers from Danfoss is designed for ammonia systems and can be used for applications such as Condensers, flooded and pumped evaporators, Sub-coolers, Desuperheaters, Superheaters, Economizers and Oil coolers.

Save time and money with MCHE standard products. The introduction of micro channel heat exchanger condensers, which combine resource and energy efficiency with minimal use of refrigerants, is enabling the development of leaner, greener solutions. Select one of our standard products and you can buy any quantity of condensers, any time, large or small, directly from stock.

SONDEX® evaporators are designed to handle advanced evaporation duties. Using semi-welded plate cassettes, the media are guaranteed to never mix. The plate cassettes are designed to ensure the optimal level of turbulence on both sides, while providing an even distribution of the media for superior performance and product quality.

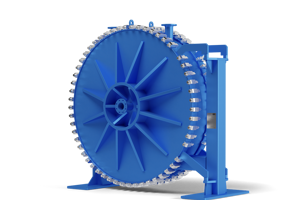

Exceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibers and solids, our SONDEX® Spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids. The design allows for a countercurrent flow that makes it possible to achieve very close temperature approaches.

Our SONDEX® Plate and shell heat exchangers (SPS) are perfect choices for condensation and steam heating duties. A fully welded plate pack makes the heat exchangers well-suited for handling aggressive media as well as high pressure levels and temperatures. Less space demanding and much lighter in weight, they are good replacements for shell and tube heat exchangers.

FAQ

What kind of heat exchanger is right for me?

The choice of heat exchanger depends on many factors. Our skilled sales engineers design the heat exchanger with the appropriate dimensions and correct specifications based on your input and requirements, to ensure that you receive a quality solution that performs optimally.

Which certificates are available for the heat exchangers?

Our heat exchangers are approved and certified according to industry standards and requirements. For specific details, please reach out to your local SONDEX® brand sales representative.

Where can I get a price list?

Please contact your local SONDEX® brand sales responsible.

How can I get a quotation?

Please contact your local SONDEX® brand sales office. For the most accurate quotation, please prepare the following data:

- Duty,

- Type of media,

- Pressure drop,

- Flow rate,

- Working pressure,

- Thermodynamic properties, Temperature,

- Working temperature.