Cranes in mining and mineral processing

To optimize crane and hoist performance, Danfoss offers flexible control strategies combined with energy efficiency, operating within stringent safety requirements.

Danfoss Drives smart features for cranes

Sensorless antisway

Integrated functional safety

Mechanical brake control

Shock load prevention

Slack rope prevention

Catch dropping load

Crane applications served by Danfoss drives

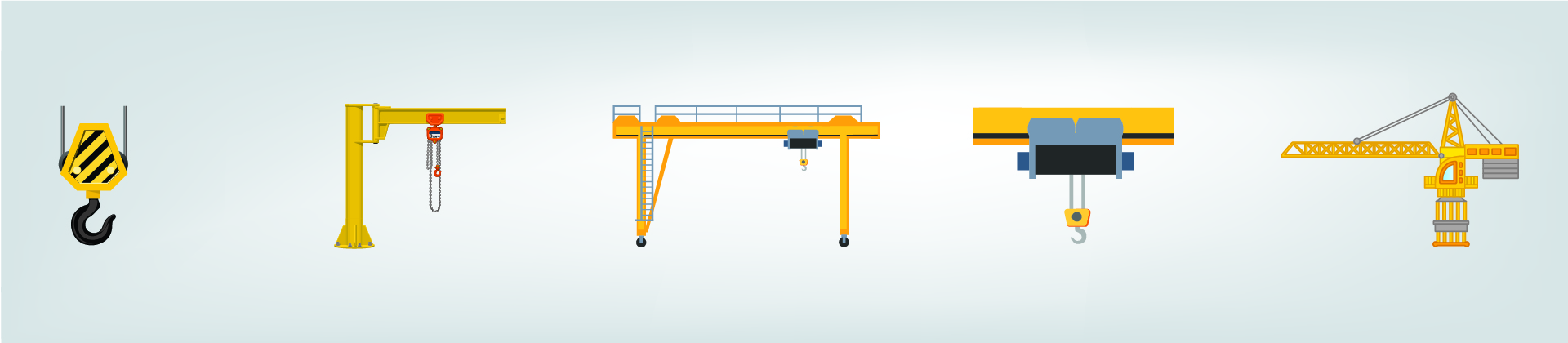

- Hoist: Lifting and lowering of the load.

- Bridge, gantry, or long travel: The part of an overhead crane consisting of girders, trucks, end ties, walkway and drive mechanism which carries the trolley and travels in a direction parallel to the runway.

- Trolley, or cross travel: The unit carrying the hoisting mechanism which travels on the bridge rails. The trolley run on a single motor or two motors coupled with common shaft.

- Jib or boom: The horizontal member supporting a moveable hoist fixed to a wall or to a floor-mounted pillar is known as a jib crane.

- Slewing: The angular movement of a crane boom or crane jib in the horizontal plane, as seen for example in tower cranes.

Crane types served by Danfoss drives

- Bridge crane

- Overhead crane

- Process crane

- Rail-mounted gantry crane

- Rubber tired gantry crane, RTG crane

- Goliath crane

- Grab crane

- Ship to shore crane (STS crane), container crane, port crane

- Marine crane

- Mobile crane

- Mobile harbor cane

- Tower crane

- Construction hoist

Danfoss Drives success stories for cranes

Burj Khalifa reaches for the sky

Controlling a 3000t slew crane on Chinese offshore pipe-laying vessel

Efficient brake control for Mukand cranes in India

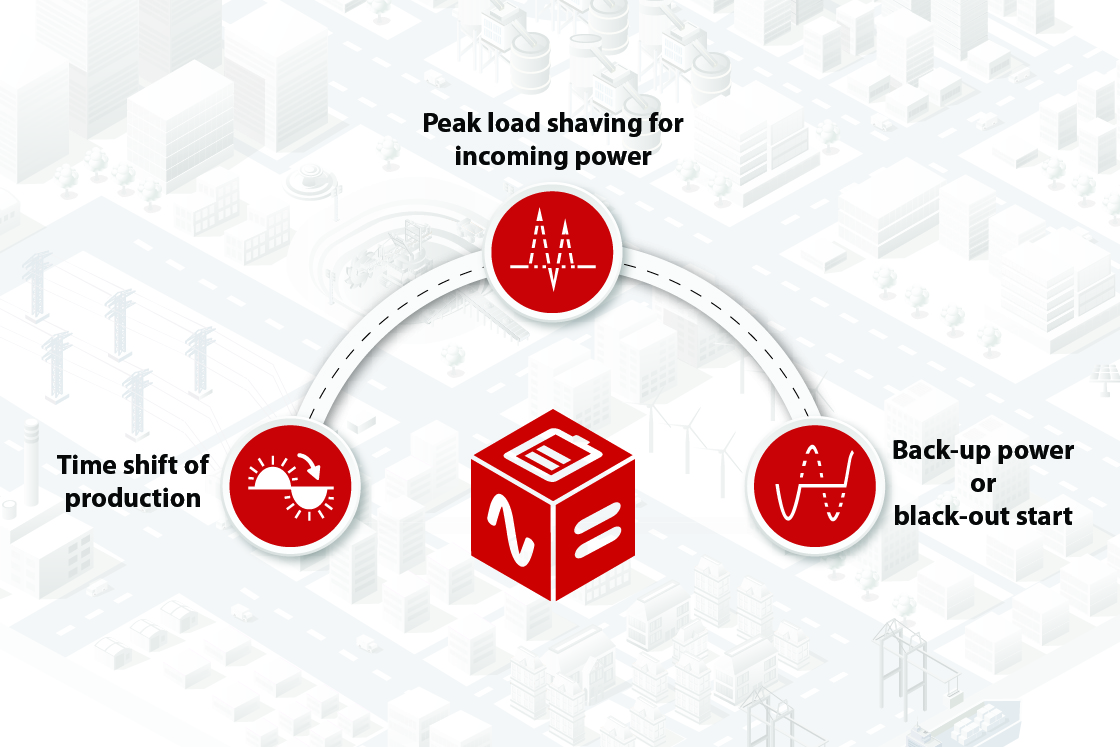

Hybridization for cranes

The future of energy is now – it’s storage

Hybridization in the form of energy storage is one of the leading recent technologies and is rapidly becoming a megatrend. Energy storage offers us flexible ways to make supply and demand meet by bridging the lag between energy generation and consumption, dampening peak loads and bridging outages.

Danfoss AC drives for cranes

VACON® NXP Air Cooled

VLT® AutomationDrive FC 302