Meeting the requirements

Joysticks are sophisticated components in the man-machine interface.

At Danfoss, we develop and update our range continuously to meet the growing functional and safety requirements of today’s mobile machines.

From time to time, this means phasing out older products to make way for the newest technology and ergonomic designs.

To support customers during the phasing-out period, we continue to supply these joysticks as legacy products.

The following legacy joysticks are currently available:

Related products

-

if (isSmallPicture) {

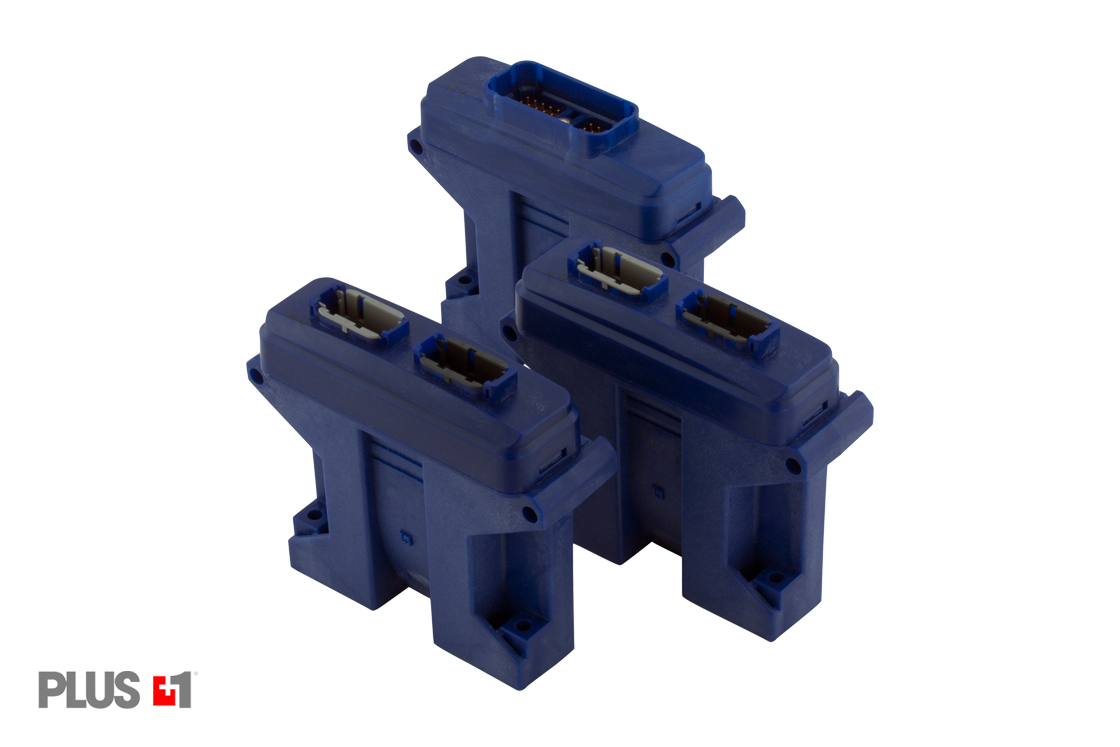

PLUS+1® input/output modules

PLUS+1® input/output modulesOur CAN-based PLUS+1® input/output (I/O) modules are stackable microcontroller add-ons providing smooth and effective hydraulic vehicle control functions.

-

if (isSmallPicture) {

PLUS+1® high current controllers

PLUS+1® high current controllersOur PLUS+1® high current controllers, with their smart design and easy to program features, provide smooth control for high-current hydraulic applications.

-

if (isSmallPicture) {

PLUS+1® SC microcontrollers

PLUS+1® SC microcontrollersFlexible, powerful and functional safety compliant SC controllers join the portfolio of PLUS+1® compliant components.

-

if (isSmallPicture) {

PLUS+1® MC microcontrollers

PLUS+1® MC microcontrollersOur powerful PLUS+1® microcontrollers bring intelligence to every node of a distributed control system. And they are equally effective for stand-alone control in smaller machines.

-

if (isSmallPicture) {

Bidirectional foot pedal

Bidirectional foot pedalRugged design bi-directional pedals with 3 million cycle operating life.

Related applications

-

if (isSmallPicture) {

Agriculture

AgricultureFarmers need agricultural machines that deliver the same high productivity every season. Hydraulic solutions from Danfoss ensure world-class performance from each machine, and a comfortable, stress-free working environment for their operators.

-

if (isSmallPicture) {

Construction

ConstructionSpace is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

-

if (isSmallPicture) {

Crane and material handling

Crane and material handlingCranes and other large handling machines are required to operate within very specific load ranges. Danfoss provides pressure transmitters that supply load limiting systems with crucial data, safeguarding your equipment, your load, and your operator.

-

if (isSmallPicture) {

Forestry

ForestryRough, sloping terrain and cramped working conditions call for robust and reliable forestry machines. We make sure you can manage everything from cutting trees and transport to preparing the forest floor for replanting. We have the smart hydraulic solutions your machines need for precise and efficient forestry operations.

-

if (isSmallPicture) {

Heavy machinery

Heavy machineryThink about the heaviest challenges in the open mining, road building and construction industry. Tasks such as cutting through rock or the Arctic permafrost; compacting thick layers of hot asphalt. As well as lifting huge, prefabricated wall panels into place.

-

if (isSmallPicture) {

Lawn and turf

Lawn and turfLawn and turf machines must adapt to their surroundings and the season – becoming sweepers or snow blowers as required. At Danfoss, we make hydraulic solutions to provide that flexibility and ensure safe and efficient operation.

Related solutions

-

if (isSmallPicture) {

Propel

PropelWe can partner with you to design and implement hydrostatic drive solutions. That provide operators with machines that are easier to maneuver. We are committed to helping you provide a more profitable investment for your customers.

-

if (isSmallPicture) {

Steering

SteeringAs the global market leader in steering components and systems, Danfoss equips everything from small lawn machines to the largest dump trucks.

-

if (isSmallPicture) {

Total machine management

Total machine managementOur PLUS+1® platform delivers the software application development power you need — and doesn’t require specialized programming skills.

-

if (isSmallPicture) {

Work functions

Work functionsOur total systems approach integrates advanced Danfoss hardware and software to deliver exceptional work function control.