Heavy-duty joysticks

As a small or medium-sized manufacturer, you need to adapt joysticks to customer needs. Just as quickly and flexibly as a large OEM. That calls for flexible components and a lean development process.

The new JS1-H family of heavy-duty joysticks provides you with a wide portfolio of ergonomically designed, modular components. Which are all fully compliant with PLUS+1® toolbox.

Brought together in intelligent joystick solutions, they provide the safety, reliability and performance. These ensure every job is done efficiently, well and in perfect comfort for machine operators.

The JS1-H joystick family offers versatile solutions for heavy-duty mobile machinery. For instance, wheel loaders, dozers, dumpers, trenchers and haulers in the construction market. As well as, pavers, graders, rollers and milling machines for road building.

Features

Rugged design up to IP66 overall

Ergonomic left, right and straight grips

Single and dual axis spring-return

Single axis w/ adjust. Friction-hold

Redundant hall effect or long-life potentiometric sensing (full redundant)

5 different output types: CAN (J1939, CANopen), CAN+ and CANalog PVE and Analog, PWM

5 different grip types: ST2- ST7- PR2- PR7*)- and HR1-grip

Several grip functions: domed and flat push-button (max. 12), proportional roller, rocker switch and FNR, operator presence switch

Connection: wiring harness with connector

Grip travel :+18°

EMI/RFI: 150V/m

ESD: 20kV

Benefits

Customizable solutions

The JS1-H base and grip options allow you to fulfill specific customer requirements for a smooth, comfortable and reliable operation. Choose from three bases and five ergonomic grip types with flexible button and switch placement.

Smart compatibility

Compatible grip and base options make joysticks simple to upgrade. Six standard electrical interfaces are available for ease of configuration.

Superior performance

The JS1-H family is suitable for almost any machine that requires joystick control. PLUS+1 Compliance enables simple and seamless future-oriented integration in the machine control system.

Faster, more flexible fulfillment times

The JS1-H standard portfolio is readily available, enabling you to reduce your warehouse stocks. Even without compromising your ability to fulfill the specifications of individual customers. Easy integration with PLUS+1 also secures fast and efficient development times.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Data sheet | JS1 Heavy Duty Joystick Family Data Sheet | English | Multiple | 11 Jun, 2019 | 677.4 KB | |

| Data sheet | JS1 Heavy Duty Joystick Family Data Sheet | Japanese | Japan | 27 Jul, 2018 | 1.2 MB | |

| Data sheet | JS1 Heavy Duty Joystick Family Data Sheet | Chinese (CN) | Multiple | 19 Nov, 2020 | 882.5 KB | |

| Data sheet | JS1 Heavy Duty Joystick Family Data Sheet | Chinese (CN) | China | 02 Nov, 2018 | 785.8 KB | |

| User guide | JS1 Heavy Duty Joystick Family Technical Information | Chinese (CN) | China | 30 Apr, 2021 | 10.3 MB | |

| User guide | JS1 Heavy Duty Joystick Family Technical Information | Italian | Multiple | 14 Jul, 2021 | 10.0 MB | |

| User guide | JS1 Heavy Duty Joystick Family Technical Information | English | Multiple | 15 Apr, 2024 | 10.0 MB | |

| User guide | JS1 Heavy Duty Joystick Family Technical Information | English | Multiple | 23 May, 2023 | 9.9 MB | |

| Data sheet | PVG x JS1-H Data Sheet | English | Multiple | 12 Jan, 2021 | 544.9 KB |

Downloads

Related products

-

if (isSmallPicture) {

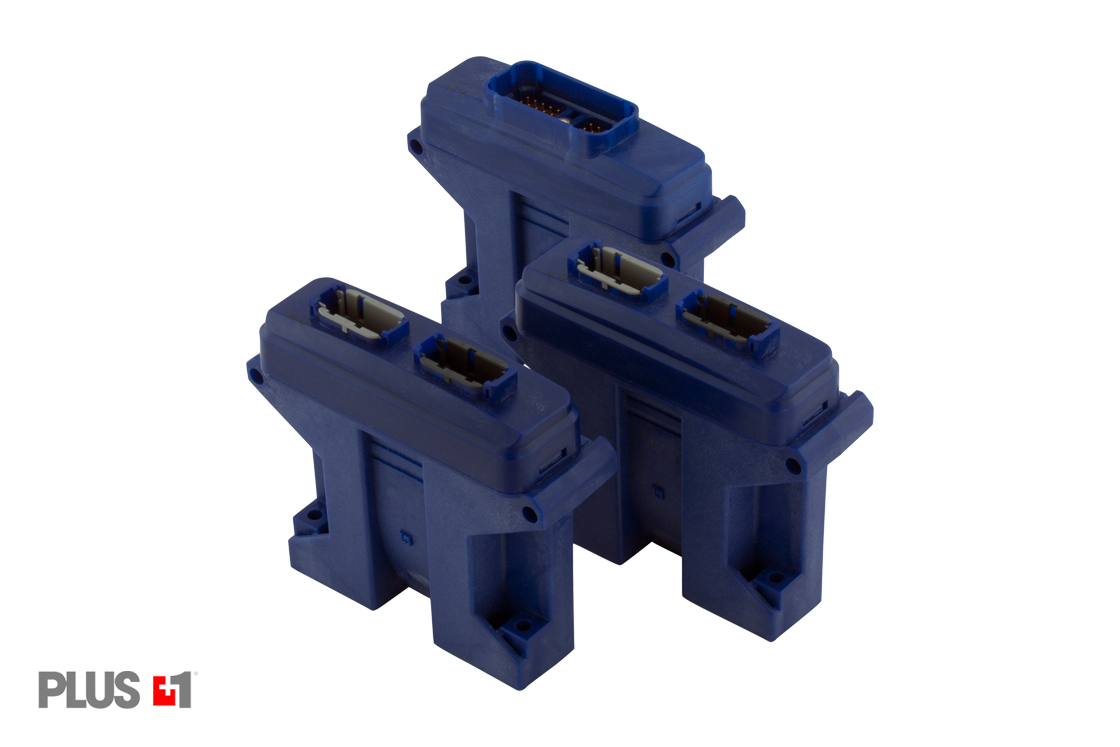

PLUS+1® input/output modules

PLUS+1® input/output modulesOur CAN-based PLUS+1® input/output (I/O) modules are stackable microcontroller add-ons providing smooth and effective hydraulic vehicle control functions.

-

if (isSmallPicture) {

PLUS+1® high current controllers

PLUS+1® high current controllersOur PLUS+1® high current controllers, with their smart design and easy to program features, provide smooth control for high-current hydraulic applications.

-

if (isSmallPicture) {

PLUS+1® SC microcontrollers

PLUS+1® SC microcontrollersFlexible, powerful and functional safety compliant SC controllers join the portfolio of PLUS+1® compliant components.

-

if (isSmallPicture) {

PLUS+1® MC microcontrollers

PLUS+1® MC microcontrollersOur powerful PLUS+1® microcontrollers bring intelligence to every node of a distributed control system. And they are equally effective for stand-alone control in smaller machines.

-

if (isSmallPicture) {

Bidirectional foot pedal

Bidirectional foot pedalRugged design bi-directional pedals with 3 million cycle operating life.

Related applications

-

if (isSmallPicture) {

Agriculture

AgricultureFarmers need agricultural machines that deliver the same high productivity every season. Hydraulic solutions from Danfoss ensure world-class performance from each machine, and a comfortable, stress-free working environment for their operators.

-

if (isSmallPicture) {

Construction

ConstructionSpace is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

-

if (isSmallPicture) {

Crane and material handling

Crane and material handlingCranes and other large handling machines are required to operate within very specific load ranges. Danfoss provides pressure transmitters that supply load limiting systems with crucial data, safeguarding your equipment, your load, and your operator.

-

if (isSmallPicture) {

Forestry

ForestryRough, sloping terrain and cramped working conditions call for robust and reliable forestry machines. We make sure you can manage everything from cutting trees and transport to preparing the forest floor for replanting. We have the smart hydraulic solutions your machines need for precise and efficient forestry operations.

-

if (isSmallPicture) {

Heavy machinery

Heavy machineryThink about the heaviest challenges in the open mining, road building and construction industry. Tasks such as cutting through rock or the Arctic permafrost; compacting thick layers of hot asphalt. As well as lifting huge, prefabricated wall panels into place.

-

if (isSmallPicture) {

Lawn and turf

Lawn and turfLawn and turf machines must adapt to their surroundings and the season – becoming sweepers or snow blowers as required. At Danfoss, we make hydraulic solutions to provide that flexibility and ensure safe and efficient operation.

Related solutions

-

if (isSmallPicture) {

Propel

PropelWe can partner with you to design and implement hydrostatic drive solutions. That provide operators with machines that are easier to maneuver. We are committed to helping you provide a more profitable investment for your customers.

-

if (isSmallPicture) {

Steering

SteeringAs the global market leader in steering components and systems, Danfoss equips everything from small lawn machines to the largest dump trucks.

-

if (isSmallPicture) {

Total machine management

Total machine managementOur PLUS+1® platform delivers the software application development power you need — and doesn’t require specialized programming skills.

-

if (isSmallPicture) {

Work functions

Work functionsOur total systems approach integrates advanced Danfoss hardware and software to deliver exceptional work function control.

Case stories

-

if (isSmallPicture) {

Farmers’ farewell to fatigue

Farmers’ farewell to fatigueTired eyes and sore muscles. 60-year-old Giorgio Speranza used to regard that an inevitable companion during harvest. Not anymore. He recently tested the Fendt IDEAL combine equipped with IDEALDrive – a machine you steer with a joystick, not a traditional steering wheel. “Probably my most relaxed harvesting experience ever,” he says.

-

if (isSmallPicture) {

Electrohydraulic steering evolution

Electrohydraulic steering evolutionDanfoss has optimized the new generation of electrohydraulic steering. We added new features for intelligence and safety for better user experience. Furthermore, new products are underway to further meet our customers’ demands and improve comfort and safety.