Extra high-power pins

Designing smart, safe but simple systems is a real challenge on machines with multiple high-current applications, such as linear actuators, lamps and electric motors. Due to power limitations, a separate controller is typically required to drive each application.

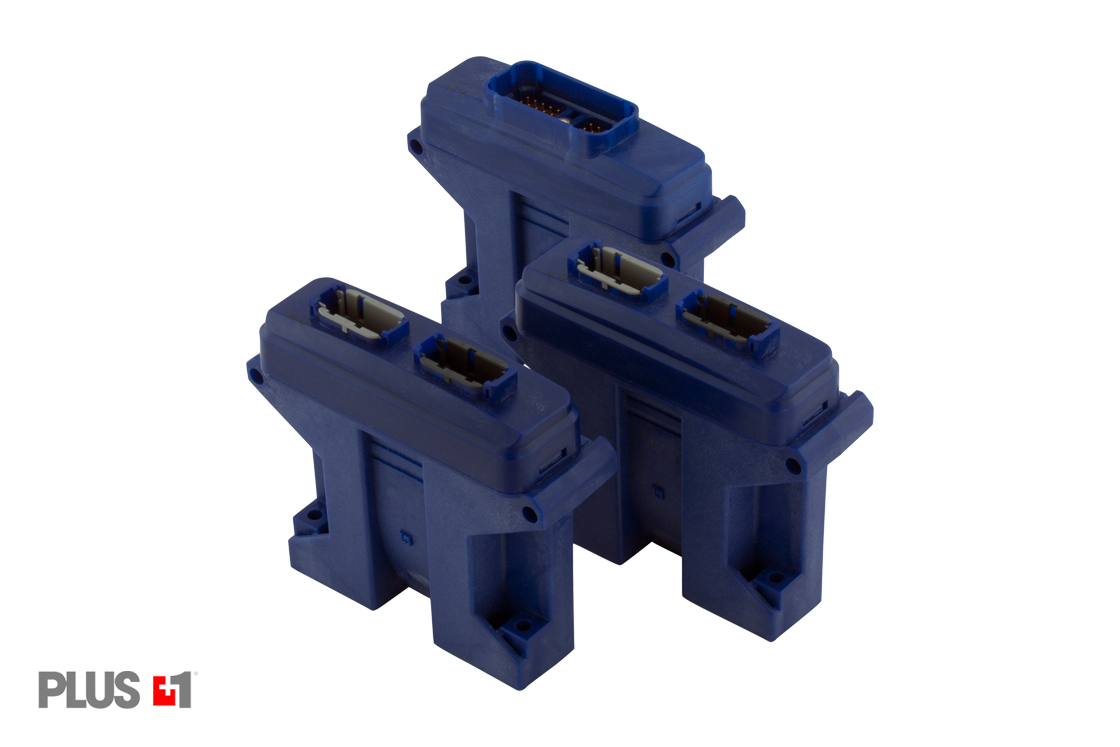

The new Danfoss MC018 high-current controller gives Original Equipment Manufacturers (OEMs) enough power to drive several applications up to a total stable current of 120A with a single controller. Extra high-power pins can also drive a particularly demanding application without compromising the performance of others. This with noiseless motor control.

As always, safety is a top OEM – and user – priority. To meet this demand, the MC018 has a separate logic power supply for intelligent fault detection. This means the controller is still able to send diagnostic information to the master controller. Even in the event of a short circuit or burnt fuse.

The simplicity and cost of a machine control system depend on the number of components used. With the MC018, OEMs gain better performance with fewer high-current controllers. Together with full PLUS+1® compatibility a fast and easy integration in advanced control systems is ensured. This is speeding up the time to market.

Benefits for OEMs

Simultaneous control of high-current applications with one controller – saving you the cost of additional controllers

Simpler system design and easy to program with PLUS+1® GUIDE – sending you faster to market and with less time spent on programming

Smoother and quieter motor control – to the benefit of the end user

Safe operation with intelligent fault detection and diagnosis

Features of the MC018

Maximum power output of 160A, with the ability to drive 120A simultaneously

Maximum power output per pin of 25A

Up to 20KHz PWM frequency at reduced load

Separate logic power supply

Easily installed power lugs

Soft fuses configurable in PLUS+1® GUIDE

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| User guide | PLUS+1® High Current Controller Family Technical Information | English | Multiple | 06 Jun, 2019 | 2.6 MB | |

| Data sheet | PLUS+1® MC018-130 High Current Controller Data Sheet | Chinese (CN) | China | 06 Jul, 2018 | 593.9 KB | |

| Data sheet | PLUS+1® MC018-130 High Current Controller Data Sheet | English | Multiple | 03 Jun, 2017 | 485.3 KB |

Related products

-

if (isSmallPicture) {

PLUS+1® input/output modules

PLUS+1® input/output modulesOur CAN-based PLUS+1® input/output (I/O) modules are stackable microcontroller add-ons providing smooth and effective hydraulic vehicle control functions.

-

if (isSmallPicture) {

PLUS+1® SC microcontrollers

PLUS+1® SC microcontrollersFlexible, powerful and functional safety compliant SC controllers join the portfolio of PLUS+1® compliant components.

-

if (isSmallPicture) {

PLUS+1® MC microcontrollers

PLUS+1® MC microcontrollersOur powerful PLUS+1® microcontrollers bring intelligence to every node of a distributed control system. And they are equally effective for stand-alone control in smaller machines.

-

if (isSmallPicture) {

PLUS+1® sensors

PLUS+1® sensorsOur temperature or pressure-detecting sensors link your machine functions to the control system. Many of the sensors in our broad range are PLUS+1® Compliant, contributing to precision control systems on all kinds of mobile application.

-

if (isSmallPicture) {

PLUS+1® XL controllers

PLUS+1® XL controllersOur new CAN-based PLUS+1® XL controllers offer a high I/O pin count for optimal vehicle control. PLUS+1® XL controllers provide space savings and optimize installation costs while meeting the latest technology needs for high-end performance.

Related applications

-

if (isSmallPicture) {

Agriculture

AgricultureFarmers need agricultural machines that deliver the same high productivity every season. Hydraulic solutions from Danfoss ensure world-class performance from each machine, and a comfortable, stress-free working environment for their operators.

-

if (isSmallPicture) {

Construction

ConstructionSpace is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

-

if (isSmallPicture) {

Crane and material handling

Crane and material handlingCranes and other large handling machines are required to operate within very specific load ranges. Danfoss provides pressure transmitters that supply load limiting systems with crucial data, safeguarding your equipment, your load, and your operator.

-

if (isSmallPicture) {

Forestry

ForestryRough, sloping terrain and cramped working conditions call for robust and reliable forestry machines. We make sure you can manage everything from cutting trees and transport to preparing the forest floor for replanting. We have the smart hydraulic solutions your machines need for precise and efficient forestry operations.

-

if (isSmallPicture) {

Heavy machinery

Heavy machineryThink about the heaviest challenges in the open mining, road building and construction industry. Tasks such as cutting through rock or the Arctic permafrost; compacting thick layers of hot asphalt. As well as lifting huge, prefabricated wall panels into place.

-

if (isSmallPicture) {

Road building

Road buildingAdvanced hydraulic systems from Danfoss deliver the machine performance that ensures road builders can meet their deadlines.

Related solutions

-

if (isSmallPicture) {

Precise work function control

Precise work function controlDanfoss precise work function control can make all the difference. Minimize your expenses, risk and machine design cycle time — and get your products in the marketplace faster.

-

if (isSmallPicture) {

Propel application library

Propel application libraryThe Danfoss Propel Application Library (PAL) is a collection of function blocks for propel applications.

-

if (isSmallPicture) {

Steer-by-wire

Steer-by-wireOur fail-safe steer-by-wire solutions allow you to remove the steering column. You can then replace it with smaller, precise steering mechanisms such as a joystick or mini-wheel.

-

if (isSmallPicture) {

Total machine management

Total machine managementOur PLUS+1® platform delivers the software application development power you need — and doesn’t require specialized programming skills.