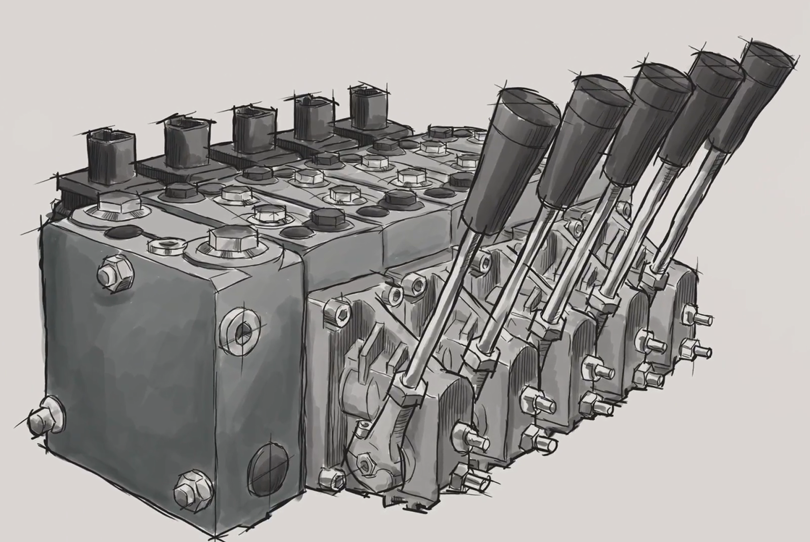

Modularity and efficiency

For the most demanding applications, only the highest flow and the highest pressure will do.

The PVG 128/256 are built to take control with up to 500 l/min per section supplied with up to 1200 l/min (300 US gal/min) pump flow.

Rock-solid control and optimum safety are more critical than ever when it comes to the biggest applications and the heaviest tasks.

This new proportional (pre-compensated) load-sensing valve series can easily be built together with PVG 32 and PVG 16 making it easy to build a valve that is adapted to the flow needs of the most demanding application.

Application opportunities

Go with our PVG 128/256 and optimize work functions on cranes, mining, drill rigs and marine applications like winches and bow thruster.

Machine benefits

Smooth load-independent flow control for optimum productivity and precise operation

Energy-efficient load-sensing technology for maximum safety and a long system life

CAN bus control for lower installation cost and increased diagnostics

Product features

Optimized for lower pressure drop and higher efficiency

Compact sectional platform solution for easy integration with PVG 16 and PVG 32

Compact design, easy installation and serviceability

Individual LS A/B relief valves ensure energy efficient, safe and reliable operation

Mechanical actuation as default on all valve sections

Hydraulic actuation

Electrohydraulic actuators PVE (Ratio metric, 0-10V, CANbus) as well as PVHC (High Current PWM) actuators

PVG proportional valves portfolio

Whether you’re moving the largest of loads or need the precise control that feels like an extension of the operator’s own hand, the family of Danfoss PVG proportional valves can address your unique challenges while delivering increased machine productivity and keeping pace with today’s shorter product cycles.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| User guide | PVG 128 and 256 proportional valve group technical information | English | Multiple | 18 Mar, 2024 | 8.5 MB | |

| User guide | PVG 128 and 256 Proportional Valve Group Technical Information | Chinese (CN) | Multiple | 21 Feb, 2022 | 8.9 MB | |

| User guide | PVG 128 and 256 Proportional Valve Group Technical Information | French | France | 20 Jan, 2020 | 8.6 MB | |

| User guide | PVG 128 and 256 Proportional Valve Group Technical Information | German | Germany | 17 Jan, 2019 | 8.1 MB | |

| Data sheet | PVG 128 and PVG 256 Proportional Valves Data Sheet | English | Multiple | 29 Oct, 2015 | 332.0 KB |

Related products

-

if (isSmallPicture) {

Series 45 open circuit axial piston pumps

Series 45 open circuit axial piston pumpsSeries 45 open circuit axial piston pumps are available in a wide range of displacements, from 25cc to 147cc with continuous pressures up to 310 bar, to fit a broad variety of applications and needs.

-

if (isSmallPicture) {

D1P open circuit high power axial piston pumps

D1P open circuit high power axial piston pumpsThe D1P is the new generation of servo controlled high power open circuit pumps. They are designed for high quality, reliability with high efficiency for easy installation.

-

if (isSmallPicture) {

PLUS+1® MC microcontrollers

PLUS+1® MC microcontrollersOur powerful PLUS+1® microcontrollers bring intelligence to every node of a distributed control system. And they are equally effective for stand-alone control in smaller machines.

-

if (isSmallPicture) {

JS1000

JS1000JS1000 is a joystick with a single- and dual-axis configurations and contact hall effect sensing.

-

if (isSmallPicture) {

JS1-H

JS1-HThe JS1-H family is suitable for almost any machine that requires joystick control. PLUS+1® compliance enables simple and seamless future-oriented integration in the machine control system.

Related applications

-

if (isSmallPicture) {

Construction

ConstructionSpace is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

-

if (isSmallPicture) {

Crane and material handling

Crane and material handlingCranes and other large handling machines are required to operate within very specific load ranges. Danfoss provides pressure transmitters that supply load limiting systems with crucial data, safeguarding your equipment, your load, and your operator.

-

if (isSmallPicture) {

Forestry

ForestryRough, sloping terrain and cramped working conditions call for robust and reliable forestry machines. We make sure you can manage everything from cutting trees and transport to preparing the forest floor for replanting. We have the smart hydraulic solutions your machines need for precise and efficient forestry operations.

-

if (isSmallPicture) {

Heavy machinery

Heavy machineryThink about the heaviest challenges in the open mining, road building and construction industry. Tasks such as cutting through rock or the Arctic permafrost; compacting thick layers of hot asphalt. As well as lifting huge, prefabricated wall panels into place.

-

if (isSmallPicture) {

Offshore oil and gas applications

Offshore oil and gas applicationsMaking up nearly 30% of global crude oil production, upstream Offshore Oil and Gas activities are some of the harshest operating environments on the planet. Drilling in waters up to 3,000 meters deep requires equipment that is reliable and safe to maximize operating productivity and prevent unexpected downtime.

-

if (isSmallPicture) {

Onshore oil and gas applications

Onshore oil and gas applicationsMaking up the majority of the world’s total oil production, onshore Oil and Gas activities require a great deal of flexibility and scalability. A variety of oil reserve types, and typically a much greater number of oil wells per reserve than offshore, onshore equipment needs to be flexible and robust.