Reliable and efficient

Safety is the highest priority when operating machines within the offshore oil and gas industry. Also, in other hazardous environments where the smallest spark is a risk. It takes specially designed components to develop a sophisticated electrohydraulic system that can drive heavy-duty work functions efficiently and safely.

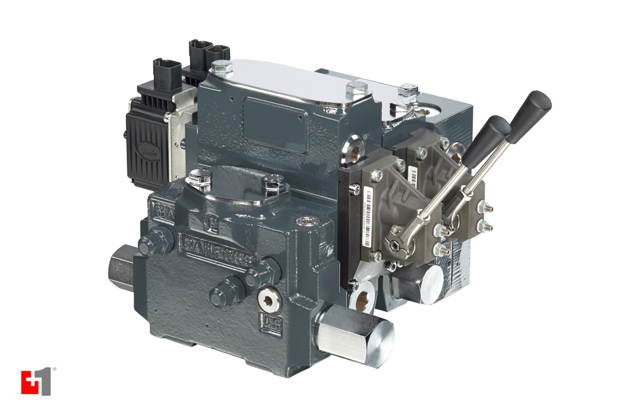

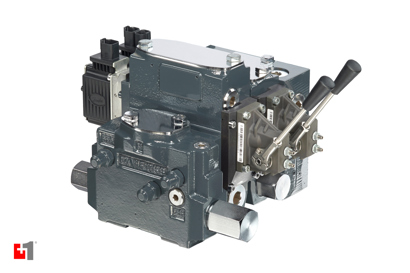

The Danfoss PVE-EX series of electrohydraulic actuators is engineered for the task, enabling the use of top-performing PVG valves in highly explosive atmospheres. Additionally, meeting complex control needs in the process.

The PVE Ex db protection variant uses a flame-proof protection method. This is crucial for use in underground mining applications and oil & gas markets. Designed with a cast iron enclosure, the PVE-EX protects the interior connectors and embedded electronics. While a protective coating on the exterior provides superior corrosion protection.

Featuring closed loop control (CLC) technology, the PVE-EX compensates for varying flow forces on the spool, internal leakage and changes in oil viscosity and pilot pressure. Feedback signals identify the source of faults or errors. As well as, the exact position of the spool so issues are quickly resolved and precision control maintained at all times.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Data sheet | Electrohydraulic Actuators PVE-EX Data Sheet | Chinese (CN) | Multiple | 27 Nov, 2019 | 4.4 MB | |

| Data sheet | PVE-EX Electrohydraulic Actuators Data Sheet | English | Multiple | 15 Sep, 2016 | 4.3 MB | |

| User guide | PVE-EX Ex db for PVG Proportional Valves Technical Information | English | Multiple | 16 Oct, 2017 | 12.2 MB | |

| User guide | PVE-EX Ex db for PVG Proportional Valves Technical Information | Chinese (CN) | Multiple | 18 Aug, 2020 | 12.7 MB |

Related products

-

if (isSmallPicture) {

PVG 120 proportional valves

PVG 120 proportional valvesLoad sensing valve suitable for high flow and pressure. The PVG 120 is built to take control.

-

if (isSmallPicture) {

PVSK

PVSKPVSK modules are ideal for applications that have specific functionality or safety requirements.

-

if (isSmallPicture) {

PVBM valve modules

PVBM valve modulesGet control of return flow with the Danfoss PVBM valve module – the only smartly integrated solution on the market.

Related applications

-

if (isSmallPicture) {

Offshore oil and gas applications

Offshore oil and gas applicationsMaking up nearly 30% of global crude oil production, upstream Offshore Oil and Gas activities are some of the harshest operating environments on the planet. Drilling in waters up to 3,000 meters deep requires equipment that is reliable and safe to maximize operating productivity and prevent unexpected downtime.

-

if (isSmallPicture) {

Onshore oil and gas applications

Onshore oil and gas applicationsMaking up the majority of the world’s total oil production, onshore Oil and Gas activities require a great deal of flexibility and scalability. A variety of oil reserve types, and typically a much greater number of oil wells per reserve than offshore, onshore equipment needs to be flexible and robust.